Cutting Tool Engineering Magazine

Cutting Tool Engineering magazine, published 12 times a year by CTE Publications Inc., helps manufacturing professionals enhance the productivity of their companies' cutting and grinding operations, and provides essential insights for machining professionals. Browse through our digital issue archive below and select the digital format you prefer: via our Cutting Tool Engineering app, a PDF file, or an interactive digital edition that can be viewed on any device by visiting digital.ctemag.com.

Get Your Printed Back Issues of CTE – Order Now!

Issue Archive

July 2021 | Vol. 73 | Issue 7

- Developing a million-hole drill

- A shot in the arm

- Making an eco-friendly industrial compound

- Tool presetting truth

- Surface grinding large plates

- Hot-rolled versus cold-rolled steel

- Give threading a whirl

- Monitoring microdrill wear and breakage

- Know how to scale down

- The skyline's the limit for this grinder

- Boring: Never dull start to finish

June 2021 | Vol. 73 | Issue 6

May 2021 | Vol. 73 | Issue 5

April 2021 | Vol. 73 | Issue 4

- E-cars: They're coming

- Designing metal alloys

- Taking cutters into their own hands

- When machining for automotive, pennies and seconds count

- Underutilizing human potential on floor

- 'To-dos' for maintaining machines

- CAM software answers the call

- Insert issues

- Lean grinding machine

- Vibratory finishing's mass appeal

March 2021 | Vol. 73 | Issue 3

- Modular drills provide advantages

- Building on a beetle

- Partnership boosts productivity

- Stainless takes flight

- Machine monitoring goes remote

- Increase feed rate or depth of cut?

- Recovery by the numbers — believe me

- Broaching revolution

- Maintain productivity when changing tools

- Cutting long, tapered surfaces

- Heavy-duty handling

February 2021 | Vol. 73 | Issue 2

January 2021 | Vol. 73 | Issue 1

December 2020 | Vol. 72 | Issue 12

October 2020 | Vol. 72 | Issue 10

September 2020 | Vol. 72 | Issue 9

- History of Joule, Watt and Coulomb

- Coolant questions

- Reusable respirators

- Out with the old machine, in with the more efficient

- Milling fixture tips

- Choose the proper grinding wheel

- Keeping track of micro parts

- Romi's D series gets makeover

- Manufacturing process can help part design

- Lights, action, video

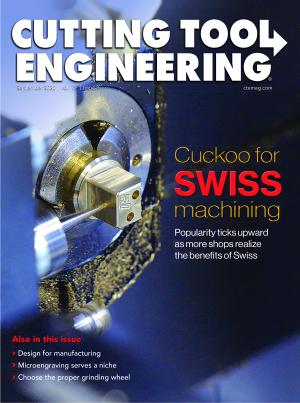

- Cuckoo for Swiss machining