Lean manufacturing concepts have been around for over 70 years, and machine shop owners are abundantly aware of the competitive benefits. By increasing value and reducing the amount of work required to perform tasks on a shop floor, many shops have experienced a transformation that has allowed them to significantly improve profitability and boost sales. A core part of lean manufacturing is the removal of waste from the manufacturing floor. The Toyota Production System identified eight wastes that are understood widely by machine shop managers.

1. Transportation. Nonvalue-added movement of parts, material and information.

2. Waiting. When people, parts, systems or facilities stand idle while waiting for a work cycle to finish.

3. Overproduction. Producing parts more quickly or in greater quantities than a customer

demands.

4. Defects. Producing parts so flawed that customers would deem them unacceptable.

5. Inventory. Accumulating leftover raw materials or finished goods that do not contribute to value creation.

6. Movement. Unnecessary movement of workers, material or equipment during a single step or at a single station.

7. Extra processing. Performing additional work even though it is not required to meet customer standards.

With the ever-widening skills gap in the machining industry, shop owners have been even more challenged by the eighth waste.

8. Underutilizing human potential. When employees can make a greater contribution yet are prevented from doing so because of other tasks they need to perform.

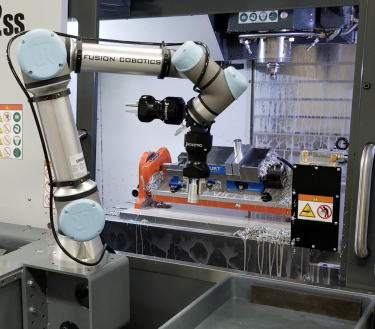

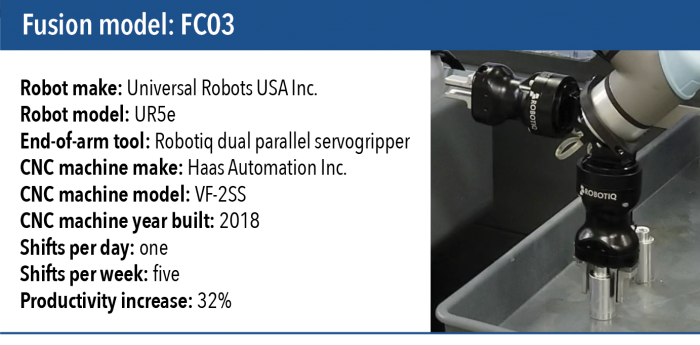

The only way that shop owners have been able to combat the final waste is by adding CNC machine tending automation. With robotic machine tending solutions on a CNC machine shop floor, workers have a better opportunity to contribute to the overall manufacturing process. As a result, shops that have embraced and applied this automation find that it is giving a competitive advantage from increased output and capacity. People are doing more cerebral work like programming, scheduling, inspecting and setting up CNCs for jobs. These shops also have benefited from attracting and retaining highly sought-after talent.

To view a video of this robotic automation at www.ctemag.com, scan the QR code with your smartphone or enter this URL on your web browser: cteplus.delivr.com/26fyy

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- lean manufacturing

lean manufacturing

Companywide culture of continuous improvement, waste reduction and minimal inventory as practiced by individuals in every aspect of the business.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.