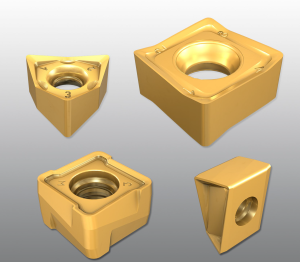

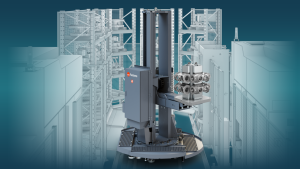

Metalworking oils for machining hard materials

Bio-SynXtra metalworking oils from Renewable Lubricants are designed for heavy-duty machining applications including stamping, drawing, milling, drilling, turning, grinding, honing, broaching, thread cutting, tapping, and other applications in hard materials like stainless steel, Inconel, and Hastelloy. The biosynthetic blend is transparent to allow visibility during cutting operations. Formulated with natural and synthetic esters, it reduces...