In the groove

In the groove

Take the plunge with the best grooving tools and techniques for the job.

When a grooving operation is required, don't plunge in without giving careful thought to what you'll be using and how to go about the task. Specific items that should be considered include proper preparation, tool and process options and what the latest technology has to offer. Time spent upfront on these important topics can pay off in longer tool life, faster cycle times and better grooving results.

Shops can get off to a good start with grooving by making sure the tool in the lathe turret is perpendicular to the workpiece surface.

If the tool isn't, "the edge of your tool is going to be tilted, so you could potentially be running scrap parts," said Clay East, national product manager for grip systems at Iscar Metals Inc. in Arlington, Texas.

He recommends running an indicator along the length of the tool to check perpendicularity. For a 102 mm (4") tool length, the measurement should be off by no more than about 0.1 mm (0.004"), he said.

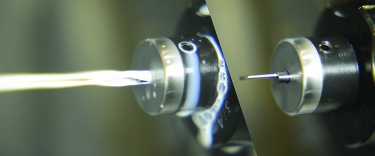

Common grooving options today include solid-carbide tools and indexables. When it comes to grooving, the focus at Scientific Cutting Tools Inc. in Simi Valley, California, is mainly on grinding solid-carbide tools for cutting internal grooves for things like threads and O-rings, said Sales Director Todd White.

Jet-Cut coolant-through tools deliver coolant to the cutting edge. Image courtesy of Iscar Metals

"These can be challenging if they are at the bottom of a small-diameter hole," he said. "You've got to have the proper reach to get to the groove (location) and then be able to machine it successfully."

For deep grooving applications, the company typically produces solid-carbide tools because of their superior rigidity. White pointed out that the allowable length-to-diameter ratio for carbide tools is 10-1 compared with 3-1 for indexable toolholders made of steel.

Custom solid-carbide round tools are a specialty at Mikron Corp. Monroe in Connecticut.

"When customers come to us for grooving tools, it is usually for a turnkey operation" — that is, a job for which Mikron produces most if not all of the different tools needed to make a part, said Sales Manager Nathan Lisker.

Provided with a part drawing or the part itself, Mikron will grind a tool designed for the special form or profile to be grooved into the part.

Indexable Issues

When indexable tools are used for grooving, "many times your chipbreaker is a big key to success," said Travis Coomer, national key account manager at GWS Tool Group in Tavares, Florida.

He advises those who use inserts to cut grooves to make sure the chipbreaker folds the chip in a way that makes it smaller than the groove being cut.

If the chipbreaker doesn't, Coomer said, "the chips will get stuck, especially once you get down into the groove a little bit. This will cause some marring of the parts."

If the groove to be cut isn't too deep, he believes that Top Notch-style inserts may be a good choice. These feature molded notches on the top and bottom that seat the inserts in their holders. With the inserts held at a 3-degree angle, the notches pull them back into the pocket during cutting, he explained, making the system very rigid and stable.

Many part designs include a chamfer at the top of the groove to eliminate burrs. In these cases, shops can opt for grooving inserts that incorporate chamfering, said Coomer, whose company makes such inserts. By cutting the groove and chamfer at the same time, users eliminate a secondary operation to create the chamfer when the groove is finished.

Another timesaving option he recommends is using a multigroove tool to cut multiple grooves right next to each other. To simultaneously cut four adjacent grooves, for example, shops can use an insert with four adjacent cutting edges.

If chamfers are on the top of the grooves, Coomer said the insert can be modified to create those features as well, "so you can cut all four grooves and put chamfers on them in one shot."

A single insert also can be used to combine grooving and turning processes. This wasn't the case back when East worked at a machine shop.

"Even if the groove was wider than it was deep," he said, "if it had 90-degree corners, you would take a groove tool and plunge all of that material out. Today, we want to apply a groove/turn solution in these cases."

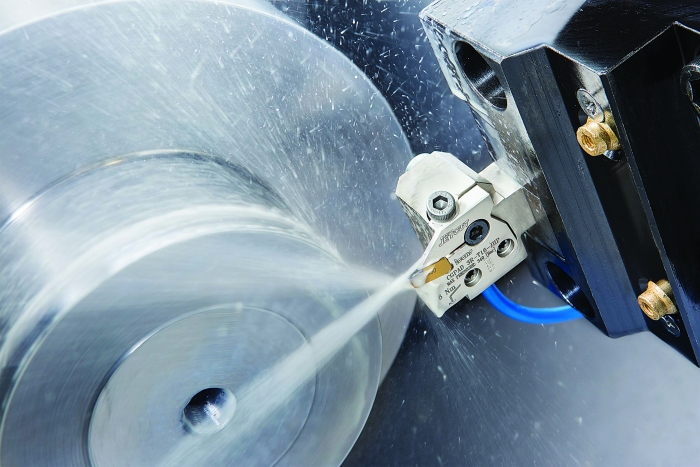

Coolant Ring Technology holders allow better coolant penetration into a bore during cutting operations. Image courtesy of Scientific Cutting Tools

East said groove/turn operations used to require two things. One was that CAD/CAM companies had to be pressed to create code for the work. Also, he said a special type of insert was needed, one with a chipformer on the front for plunging, plus a chipformer on each side for turning.

With inserts like this, "you can plunge down and then start side-turning to remove material as well," he said.

East said one reason to opt for a groove/turn operation is that chip control is easier when turning than when plunging. In addition, he said groove/turn processes reduce cycle time because metal removal rates are usually "a lot better" than those achieved with plunging.

When a groove is very wide, White warns that cutting it all at one time can put too much pressure on the tool, causing deflection problems and even breakage. So in cases like this, he believes that a better approach can be to employ a peck cycle — in other words, making a couple of passes to depth using a tool that's thinner than the groove, then moving the tool over a little and doing the same again. Besides going easier on the tool, he said a peck cycle gives a chance to flush out potentially problematic chips.

Cool Developments

Effective chip removal is particularly important during internal grooving operations.

"If you can't get the chips out of the bore," White said, "usually you will re-cut them, and then they will scar the surface."

Moreover, when a lot of chips accumulate, he said they can wrap around a tool and break it.

Chip problems like these can be prevented by improved coolant delivery, which is possible today thanks to several developments. One is the increased coolant pressures produced by current machines. White said these pressures typically range from 300 psi all the way up to 1,000 psi.

"That is a great advancement specifically for grooving," he said.

Another is the variety of coolant-through tooling options available. As the name suggests, this type of tooling features internal passages for coolant flow. White said many different toolholders feature coolant-through designs that get coolant right to the cutting edge to lessen thermal degradation of the substrate.

Lisker said coolant-through technology is especially helpful when cutting nickel-base alloys like Inconel that transfer heat back to the tooling. Besides maintaining thermal stability on the cutting edge, he said coolant-through systems disperse chips to help with chip control.

Mikron works with customers to produce the best solid-carbide grooving tools for applications. Image courtesy of Mikron

"If (the tool) is going on a lathe, our message is to use coolant-through tooling as a first choice," said East, whose company offers tooling products of this type called Jet-Cut.

When customers ask why they should pay more for Jet-Cut holders, he points out that coolant pinpointed on the cutting edge increases tool life, which translates into more parts per edge. He notes as well that efficiently delivered coolant quenches chips and makes them brittle, so they break up more easily.

Grooving also goes better these days thanks to advances in tool coatings. The latest coating materials are heat- and wear-resistant, which increases tool life. White said they additionally improve speeds and feeds by preventing workpiece materials from sticking to tools.

Among the coatings that Scientific Cutting Tools uses for grooving tools are diamondlike carbon coatings, such as ta-C, which he describes as a very hard, thin coating that works well on tools used to cut abrasive nonferrous materials.

White makes a strong case for shops to spend extra for coated grooving tools.

In some instances, he said, "a coated tool is only a few dollars more than an uncoated one. But in the right materials, it can give you three to five times the tool life of an uncoated tool. So you get a great return for a small investment in the tool."

Glossary terms in this article