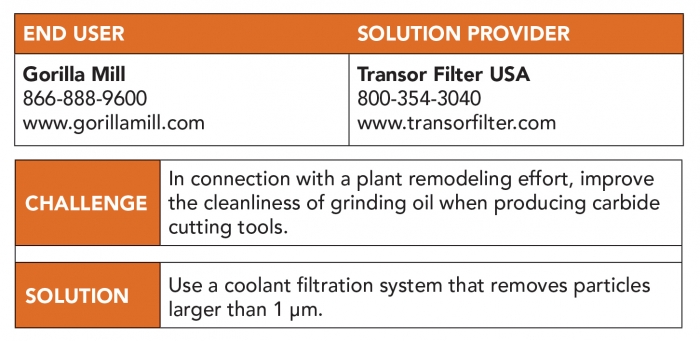

Remodeling a plant offers an ideal opportunity to improve production and enhance the working environment. Gorilla Mill realized those gains when the cutting tool manufacturer remodeled its plant in Waukesha, Wisconsin.

“Our plant remodeling involved a series of calculated decisions to provide the simplest, cleanest and most efficient method of machine layout,” said Operations Manager Nathan Cranker.

He said part of the remodeling involved installing two troughs, or trenches, that extend about 50.3 m (165') — or 90% of the addition — and supply Gorilla Mill’s tool and cutter grinders with electricity, air and coolant infeed and drainage.

The former arrangement was chaotic “because of all the wires, cables and hoses hanging from the ceiling,” Cranker said. “There might have even been a few goats and chickens wandering around.”

In the past, he said the company employed a grinding oil filtration system that used paper filter-type media, which wasn’t effective at keeping the oil clean.

“The coolant looked like coffee,” Cranker said.

To improve coolant cleanliness, he said the toolmaker switched to vessel filtration machines from Transor Filter USA in Elk Grove Village, Illinois. Each one serviced two to three grinders.

“When we transitioned to Transor,” Cranker said, “it kept the coolant mostly clear with a slight honey-colored hue.”

To coincide with the plant remodeling, he said Gorilla Mill sought a new filtration system and considered canister-type filtration. However, that system would have complicated the recovery of carbide sludge, which sells for about $8,000 per 208.2-L (55-gal.) drum. The company generates a drum of sludge roughly every two weeks.

Having had experience with Transor Filter, which is about two hours from Waukesha, Gorilla Mill purchased a V-series filtration system to service 18 grinders and placed it in a separate room adjacent to the machining area. According to Transor Filter, the system delivers clean oil that’s temperature-controlled to ±1 degree C to each machine upon demand, and automatic backflushing self-cleans the filter elements to minimize maintenance. The automated sludge handling system additionally features a drag-out that brings sludge out of Transor Filter’s unit and dumps the sludge into a drum.

Cranker said the oil temperature is kept at 22 to 24 degrees C (71.6 to 75.2 degrees F).

The production area also maintains a fairly constant temperature to help hold tool size.

“We don’t allow any doors to be opened for an extended time during the summer no matter how nice it is,” Cranker said.

By keeping the filter and chiller in a separate room, he said Gorilla Mill is able to recirculate heated air during cold months via ducts and diverters.

“It also removes warm air from the maintenance room to the outdoors during the warm months,” Cranker said.

This energy efficiency annually saves about $3,000 to $5,000.

Besides consistently precise tools, Gorilla Mill President Kevin Cranker said customers demand aesthetically pleasing tools.

“One of the additional benefits of the Transor system is that our tools’ surface finish is incredible,” he said. “There’s just something about a great-looking tool that seems to add to its performance.”

Kevin said Transor Filter’s One Micron Filtration extends the life of diamond wheels.

Gorilla Mill houses the V-series filtration system in a separate room at its plant. Image courtesy of Transor Filter

“Not having buildup on the wheel enhances their performance,” he said, “and the chilled oil enables us to maintain the thermal stability required for consistent toolmaking.”

Nathan said the lubricity of oil allows diamond wheels to impart a glasslike finish, and the oil also keeps the carbide workpiece cool, protecting it from microfracturing.

“Obviously, the best fluid for cooling is water,” he said. “However, oil keeps our machines from turning into concrete, which can happen when water and carbide sludge mix.”

In addition, Nathan said having clean coolant helps keep the oil’s flashpoint high to prevent oil from exploding.

“We’ve had one before,” he said, “and it was scary. That was when we were on the media paper filter unit.”

As production and the number of grinders increase, the system’s modular design enables more filter modules to be added. At Gorilla Mill’s current rate of growth, Nathan said the company plans to add about 10 to 12 more grinding machines in the next five years.

“COVID obviously slowed things down,” he said, “but we fought our butts off and stayed about even through 2020. Now things are trending up again, and we are focused on massive growth.”

Kevin said he expects Gorilla Mill to double its production in the next five to 10 years and that the V-series filtration system will help achieve that goal while keeping the facility clean.

“Machining carbide is a really dirty business,” he said. “Having the centralized filtration and mist collection keeps plant maintenance to a minimum.”

Regarding his vision for the future of the company, Kevin joked, “World domination. It can be like

a jungle out there, and either you’re the hunter or the hunted. We have plans to expand to several additional countries in the near future.”

Contact Details

Contact Details

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- lubricity

lubricity

Measure of the relative efficiency with which a cutting fluid or lubricant reduces friction between surfaces.

- micron

micron

Measure of length that is equal to one-millionth of a meter.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- modular design ( modular construction)

modular design ( modular construction)

Manufacturing of a product in subassemblies that permits fast and simple replacement of defective assemblies and tailoring of the product for different purposes. See interchangeable parts.

- recovery

recovery

Reduction or removal of workhardening effects, without motion of large-angle grain boundaries.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.