By Esprit CAM

Emergency responders require the best tools available to fulfill challenging jobs. In critical life-and-death situations, every second matters. Countless firefighting, policing and other first-response organizations worldwide count on Holmatro Inc. in Glen Burnie, Maryland, to equip them with the most reliable, efficient tools.

To satisfy these demands, Holmatro has relied on Esprit CAM in Camarillo, California, for more than two decades. From the products that Holmatro makes to the manufacturing processes needed to complete them, efficiency is key, and Esprit CAM software allows Holmatro to machine more features in a single operation.

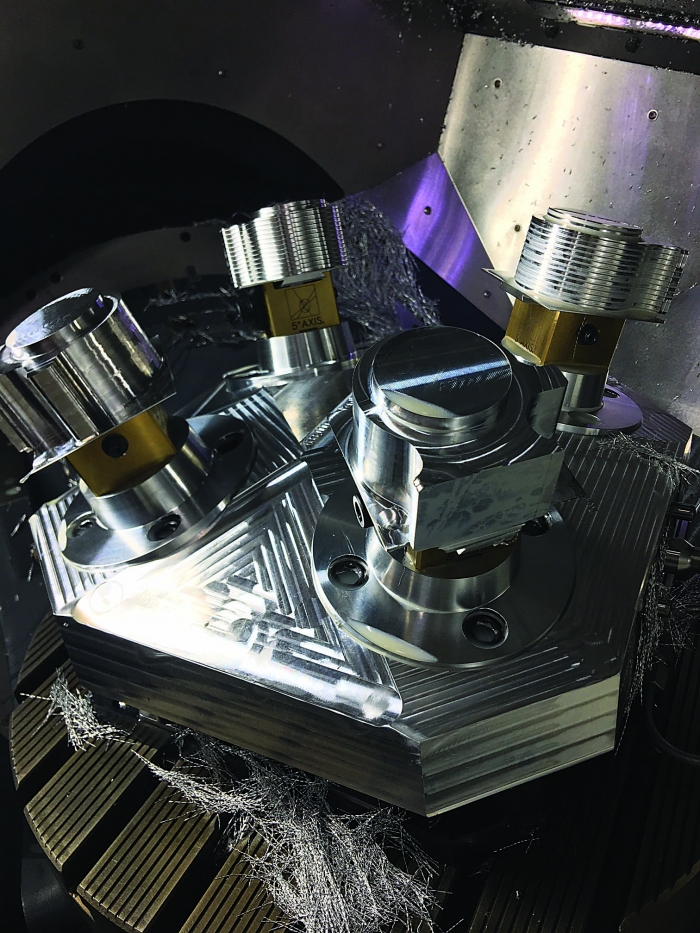

Esprit CAM can keep up with Holmatro’s high demands. Image courtesy of Espirt CAM

Since 1999, Holmatro has used Esprit CAM software to manufacture hydraulic rescue equipment like cutters and spreaders, as well as cylinders, plungers, check valves and more, from aluminum, steel and exotic alloys. Although Holmatro most often is associated with hydraulic rescue equipment, the company also makes complex parts for many demanding industries, including rail and energy.

Despite being a longtime Esprit CAM user, Holmatro is far from complacent.

“We periodically check in with our team to ensure Esprit is evolving with our needs,” said Manufacturing Engineer Chuck Cain. “Esprit was very good at multifunction machining when we bought it in 1999. A few years ago, we reviewed many other CAM packages to evaluate if we were keeping up with the times. After many demos, we concluded that Esprit was still the best choice for us. We ended up adding multiple seats of Esprit to our facility in the Netherlands.”

Holmatro’s U.S. headquarters houses more than 30 CNC machines, ranging from nine-axis mill/turn to five-axis simultaneous equipment, mostly made by DMG Mori USA Inc. and Okuma America Corp. Holmatro uses incredibly demanding processes to get the job done. Because a lot of the products save lives, there’s no room for error.

“The parts that we manufacture are complex due to the nature of manufacturing parts to such close tolerances,” Cain said. “A typical product will have tolerances not to exceed 30 µm (0.001"). We also have many products with 20 µm (0.0008") tolerances.”

Holmatro regularly uses Esprit CAM to quickly manufacture fixtures and program parts on five-axis milling machines.

“We were able to save approximately 30 minutes per part by utilizing a 3+2 machining mentality,” Cain said. “ProfitMilling also helped with cycle time reduction.”

In recent years, Holmatro has been interested in exploring how automation could improve efficiency and ultimately the bottom line. Esprit CAM’s diverse cycle selection and ability to handle any machine make done-in-one

manufacturing possible.

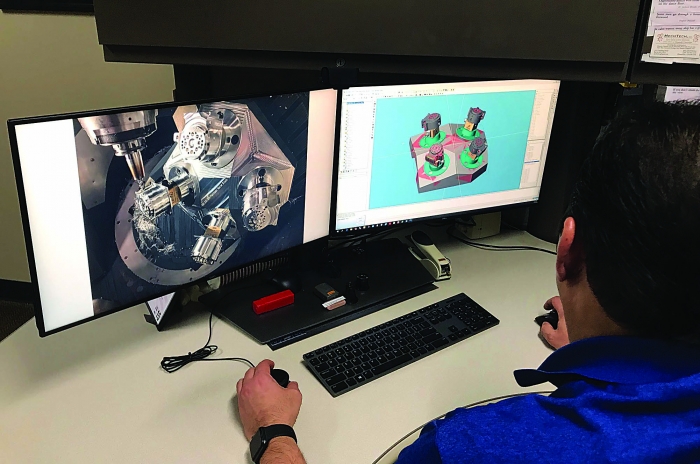

Holmatro counts on Esprit CAM to manufacture hydraulic equipment. Image courtesy of Esprit CAM

“Right now, our main focus is on enhancing production with unattended machining,” Cain said. “We always look for ways to avoid handling parts more than once or twice. We also strive to manufacture complete parts in one sequence of events. With Esprit, we are able to manufacture the fixture components in a short time.”

Holmatro seeks to improve product offerings while delivering them to the public faster and at a reasonable price point thanks to improved efficiency.

“The future of our company is about manufacturing new products and providing our customers with the quality they expect in as few operations as possible,” Cain said.

Efficiency isn’t a concept limited to manufacturing processes.

“This philosophy is especially true for our first responders,” Cain said. “We strive to provide solutions that allow the rescue team to use the least amount of equipment as possible while still being effective.”

He said one of the most interesting innovations on the horizon is cordless equipment, which would enhance the efficiency and mobility of first responders and help them more effectively save lives.

“This means no hydraulic lines that connect a hydraulic pump and rescue tool,” Cain said.

He said Esprit CAM has helped Holmatro grow since the 1990s.

“With its new cycles, techniques and software enhancements, we were always generating cost savings,” Cain said. “This also increases capacity and throughput. We look forward to the end of each calendar year because we know that Esprit CAM will be releasing some new or improved version of Esprit.”

For more information about Esprit CAM in Camarillo, California, call 800-627-8479 or visit www.espritcam.com.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.