Some machine tools never die, but they may need a retrofit to avoid the graveyard.

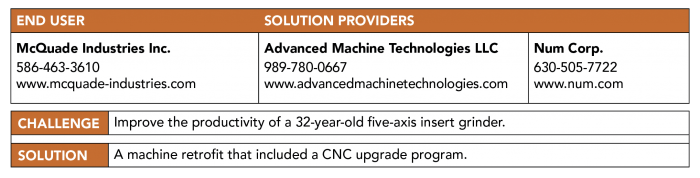

Founded in 1978, cutting tool manufacturer McQuade Industries Inc. purchased a Swiss-made Ewag RS12 five-axis CNC insert grinder, as well as a four-axis version, a decade later — machines still in use today. However, the grinders eventually started to lack the flexibility needed to produce some of the more complex geometries, and the toolmaker was experiencing long setup and cycle times, said Production Manager Donald Ostgen.

“After 30-plus years,” he said, “even the best machines can begin to show signs of their age.”

Ostgen said McQuade Industries encountered issues at times when producing the correct radii and interpolation of angles on inserts.

The Clinton Township, Michigan-based company manufactures a range of tools, including boring bars, milling cutters and generating heads, and offers tool regrinding and repair services.

Ostgen said the company considered purchasing a new Ewag grinder, but with a price tag of more than $750,000, McQuade Industries balked at making such a sizable investment.

Both Ewag grinders came with the Num 760 CNC, Num Güttinger NGS 610 servodrives and Num/Sem brushed servomotors, so McQuade Industries contacted Num Corp. in Naperville, Illinois, about retrofitting the grinders, starting with the five-axis one. Num recommended Advanced Machine Technologies LLC in Owosso, Michigan, to perform the retrofit.

AMT’s Lee Horton suggested upgrading the machine to Num’s latest-generation Flexium+ 68 CNC and replacing the drives and motors on all five axes with NumDrive X digital servodrives and new Num brushless servomotors. In addition, the grinder was fitted with a new Num FS-12 touch-sensitive operator’s panel, an MP08 machine panel and an HBA series portable hand wheel. The variable-frequency drive for the existing grinding spindle also was replaced with a NumDrive X servodrive. This approach has the advantage that all command, feedback and status information is exchanged over a fast digital bus, which reportedly simplifies wiring and improves diagnostic capabilities.

The five-axis Ewag RS12 insert grinder is shown prior to being retrofitted. Image courtesy of Num

“We need these machines to do what we do,” Ostgen said. “So for about $100,000, we upgraded one, and it’s the best thing we did in a long time.”

For the retrofit, he said AMT took the electronic cabinet to its facility to install new wiring and mount the drives while it mounted the motors and worked on other mechanical components at McQuade Industries’ shop. Because finding spare parts is a challenge, McQuade Industries participated in the retrofit by making adapters and other needed items for the motors. The retrofit took about a week.

The upgrade provided full backward compatibility with part programs that McQuade Industries had created over the previous three decades. Ostgen appreciates that the new control supplies plenty of storage for the hundreds of part programs the company has.

“We don’t have to use a PC anymore,” he said. “Everything gets saved to the cloud for backup, so we don’t lose anything.”

The retrofit grinder quickly started returning the investment by cutting setup times in half and reducing cycle times by two to three minutes from about four minutes per part on the grinder before the upgrade, Ostgen said. Part runs range from about 500 to 4,000 pieces.

The RS12 grinder is displayed after the upgrade. Image courtesy of Num

He said McQuade Industries no longer must run some parts with intricate designs on a wire EDM. In addition to saving more than 10 minutes per part, eliminating EDM-ing avoids cutting carbide in deionized water, which can cause cobalt to leach from the substrate.

“You lose your edge, and your coating won’t adhere,” Ostgen said about cobalt leaching. “It makes a mess.”

To prevent that before the retrofit, the company had to thoroughly blow-dry and wipe inserts after EDMing — a labor-intensive process. In contrast, oil is applied when grinding, so leaching does not occur.

McQuade Industries plans to eventually have AMT retrofit the four-axis RS12 grinder while adding a fifth axis.

“If anyone doubts the benefits of a CNC upgrade,” Ostgen said, “they should take a look at our installation.”

Contact Details

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- interpolation

interpolation

Process of generating a sufficient number of positioning commands for the servomotors driving the machine tool so the path of the tool closely approximates the ideal path. See CNC, computer numerical control; NC, numerical control.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- wire EDM

wire EDM

Process similar to ram electrical-discharge machining except a small-diameter copper or brass wire is used as a traveling electrode. Usually used in conjunction with a CNC and only works when a part is to be cut completely through. A common analogy is wire electrical-discharge machining is like an ultraprecise, electrical, contour-sawing operation.