Contact Details

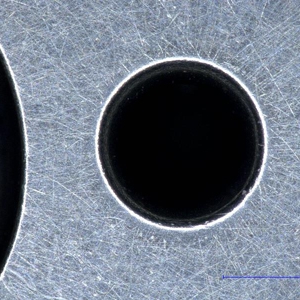

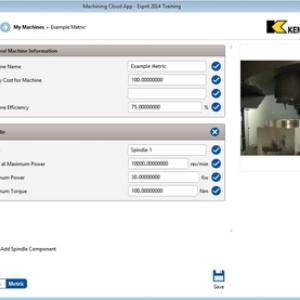

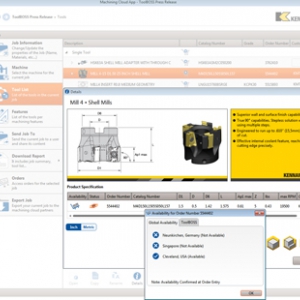

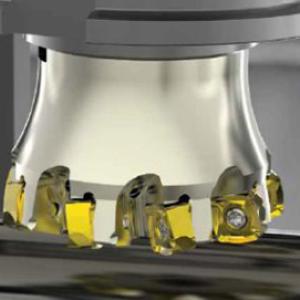

The innovative Beyond platform of high-performance tool grades from Kennametal has garnered exceptional reviews from customers worldwide. Now the company is introducing the first Beyond inserts for holemaking applications. Three new grades are available: KCPK10, KCU25, and KCU40. The product portfolio covers SPPX/SPGX Drill Fix Square (DFS) outboard inserts, available in HP, FP, and MD geometries. Together with the DFS drill bodies, diameters range from 24.0 to 55.0mm (1.00 — 2.125 inch). Kennametal's DFS indexable drill platform offers the economy of a square insert having 4 edges in the outside pocket combined with the outstanding centering and high feed ability of a DFT trigon insert. The DFS indexable drill can be used in virtually any short-hole applications and materials performed on CNC lathes or machining centers. Achieving up to 20 percent or higher material removal rate (MRR) at the same tool life as standard inserts, the KCPK10 grade offers outstanding abrasion and crater-wear resistance for high-speed machining of steels and cast irons.

Related Glossary Terms

- cast irons

cast irons

Cast ferrous alloys containing carbon in excess of solubility in austenite that exists in the alloy at the eutectic temperature. Cast irons include gray cast iron, white cast iron, malleable cast iron and ductile, or nodular, cast iron. The word “cast” is often left out.

- centering

centering

1. Process of locating the center of a workpiece to be mounted on centers. 2. Process of mounting the workpiece concentric to the machine spindle. See centers.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.