Contact Details

Iron is the most abundant element on earth by mass. For more than 25 centuries it’s been used to plow fields, build bridges, cook food, and wage war. Without iron, the Industrial Revolution would have gone nowhere, we would have no trains, automobiles or machine tools today, and mankind would still be an agrarian society. It is quite simply the

most important metal in history.

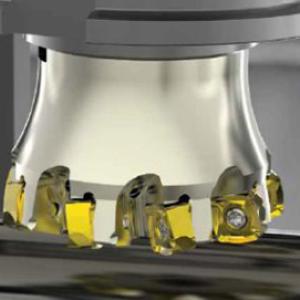

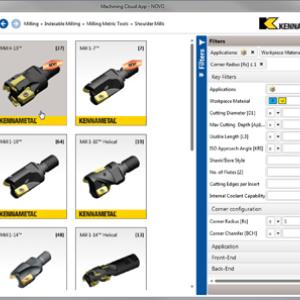

There’s a newcomer to this metal family, though, one that’s making manufacturers take notice. As automakers strive for increasingly fuel efficient and environmentally friendly vehicles, they’re turning away from traditional iron favorites such as gray and ductile iron (GCI and DCI) to compacted graphite iron, or CGI. Also known as vermiculate graphite iron, CGI’s mechanical attributes meet or exceed its counterparts, sometimes drastically so. Unfortunately, CGI is also more difficult to machine, requiring cutting tools both tough and wear-resistant. And because of the continuing call for cost-effective machining solutions across all manufacturing industries, these tools must also offer a low cost per part and predictable tool life. For facemilling applications, Kennametal says that tool is Mill 16.

“Compared to cast iron, CGI has lower weight and greater strength, and is ideal for components that are exposed to both thermal and mechanical stresses like engine blocks and heads for cars and trucks, exhaust manifolds, and brake parts,” says Marcelo Campos, senior global product manager for indexable milling. “As with other cast irons, however, it is quite abrasive, and somewhat gummy to machine. We developed Mill 16 as a best in class facemill not only for CGI, but for all types of cast iron, which remains a popular choice for gear boxes, housings, pump bodies and other components used in the automotive, agricultural and heavy equipment sectors.”

Campos outlines Mill 16’s unique strengths as follows:

-The Mill 16 has a fine-pitch and medium-pitch cutter body equipped with an innovative single-screw, wedge-style clamping system. This reduces time spent in the toolcrib setting the tool and assures rigid, no-fail tool placement. Each pocket on the cutter body is numbered, as are each of the insert’s cutting edges, assuring maximum accuracy and ease of use when indexing to a new cutting edge.

-The heart of the Mill 16 is an octagonal, double-sided insert with 16 effective cutting edges, providing the lowest tooling cost per part possible. The face of each cutting edge contains an aggressive chipbreaker for positive cutting action and increased chip flow. The wedge clamp on either side of the insert’s top face is likewise chamfered to improve chip evacuation.

-Mill 16 is available in cutter diameters ranging from 2 in. to 10 in. (50 mm to 250 mm). Kennametal has rated the maximum axial depth of cut (Ap1) at 5.5 mm (0.216 in.), although depths to 9 mm (0.35 in.) or greater are achievable, an important consideration where casting variation is a concern. Due to the cutter’s low cutting forces, up to 100 percent radial cutter engagement is possible. All cutters have internal coolant supply capability.

-The carbide is new as well. Kennametal’s grade KCK20 is a PVD AlTiN/AlTiCrN multilayer coating bonded to a wear resistant substrate which provides an average tool life of 30 percent greater than comparable TiAlN-coated grades.

-A wide assortment of insert edge preps, geometries, corner radii, as well as a number of complementary grades assure the Mill 16 is a top performer in a variety of machining conditions, from heavy roughing to semi-finishing and, because of the insert’s integrated wiper facet, fine finishing to Ra 3.2 μm or better. Customer field tests have shown consistent and positive results. During a dry machining operation on a ductile cast iron plate using Mill 16, feed rates were increased by 41 percent and tool life doubled tool. A gray iron transmission case was machined at a feed rate of 0.39 mm per tooth (0.015 in.) and cutting speed of 208 m/min (682 ft/min), leading to reduced spindle loads compared to the legacy tool and slightly improved tool life. Metal-removal rate and tool life on a water pump housing was more than doubled by switching to Mill 16.

There are more examples. Campos says he’s worked extensively with automakers and their suppliers, and in all cases the Mill 16 outperformed his competitor’s cutting tools. “We have cutting force dynamometers. We take videos. We run head to head tool life tests. For us to stand up and say we get 20 percent better tool life or 50 percent more metal removal than our next competitor, you can be certain it’s true. We at Kennametal are very excited about the Mill 16, and what it can do for our customers machining CGI and other types of cast iron.”

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- cast irons

cast irons

Cast ferrous alloys containing carbon in excess of solubility in austenite that exists in the alloy at the eutectic temperature. Cast irons include gray cast iron, white cast iron, malleable cast iron and ductile, or nodular, cast iron. The word “cast” is often left out.

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- compacted graphite iron

compacted graphite iron

Cast iron having a graphite shape intermediate between the flake form typical of gray cast iron and the spherical form of fully spherulitic ductile cast iron. Also known as CG iron, CGI or vermicular iron, it is produced in a manner similar to that of ductile cast iron but using a technique that inhibits the formation of fully spherulitic graphite nodules.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- cutting force

cutting force

Engagement of a tool’s cutting edge with a workpiece generates a cutting force. Such a cutting force combines tangential, feed and radial forces, which can be measured by a dynamometer. Of the three cutting force components, tangential force is the greatest. Tangential force generates torque and accounts for more than 95 percent of the machining power. See dynamometer.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- facemill

facemill

Milling cutter for cutting flat surfaces.

- facemilling

facemilling

Form of milling that produces a flat surface generally at right angles to the rotating axis of a cutter having teeth or inserts both on its periphery and on its end face.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- metal-removal rate

metal-removal rate

Rate at which metal is removed from an unfinished part, measured in cubic inches or cubic centimeters per minute.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.