Contact Details

ISCAR introduces the ISCAR HELIQMILL 390 line, a new step of development of the insert with helical cutting edge.

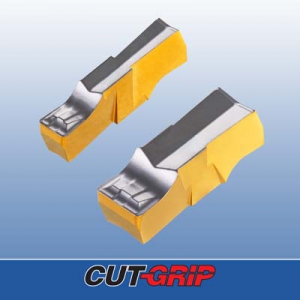

The "classical" HELIMILL insert and its further derivatives have two cutting edges. The new line offers a triangular insert with three cutting edges, one extra. Interestingly, the length of the cutting edge of an insert with three edges is the same as in an insert with two: the new inserts are available with 10 and 15mm cutting edge lengths. The insert with three edges has a stronger structure and its clamping into the pocket features high rigidity. The advanced cutting geometry of the new insert results in a precise 90 degree shoulder and a wiper flat provides excellent surface finish. The HELIQMILL 390 tools have impressive ramping-down abilities.

The new line incorporates all the advantages of HELIMILL. However, in ISCAR's new HELIQMILL 390 line, the added advantages of an extra cutting edge, extra-strong design, extra reliability and extra accuracy lead to extra performance. This provides productive milling of true 90 degrees in combination with an improved cost per cutting edge.

The HELIQMILL 390 inserts are produced from ISCAR's innovative SUMO TEC carbide grades, which contribute largely to increasing productivity.

The new tools are intended for machining shoulders, slots and planes. In addition, they can be a good choice in milling surfaces, ramping-down or helical interpolation such as pockets or cavities. The tools are available as endmills with shanks and face mills with a central bore.

Related Glossary Terms

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- interpolation

interpolation

Process of generating a sufficient number of positioning commands for the servomotors driving the machine tool so the path of the tool closely approximates the ideal path. See CNC, computer numerical control; NC, numerical control.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.