Contact Details

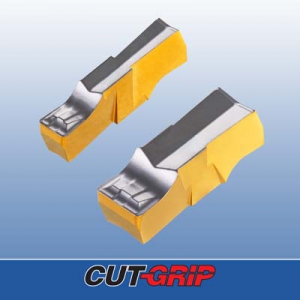

Iscar Metals Inc. says its 11mm profiling insert does the job of a bigger one, thus enabling finer-pitch cutters for smoother profiling and lower chip loads. On a 2.00"-dia. cutter, for instance, six of the new HELIDO H400 RNHU 1205 inserts can reportedly fit in a pitch circle that normally accommodates just five standard 12mm inserts. Key applications include die and mold applications and blade profiling for the aerospace and power generation industries. It should be preferred wherever standard 12mm profiling inserts are used. Thehe design secret of the H400 RNHU 1205 insert is that it isn't quite round. Each face has four 0.236" radius cutting edges separated by a flat. The result is that the insert itself measures just 0.433" across and it performs like one 0.039" larger. The smaller the insert, the more you can fit into a given-size pitch circle. Depending on priorities, the user can translate this difference in diameter to higher table feeds, finer finish or longer edge life. Made from extra-tough SUMO TEC grades, the inserts are double sided, with each edge providing a 120 degree active area. The adjacent flats prevent insert rotation in the HELIDO cutter's rigid dovetail seat pocket. Despite the negative axial orientation needed to create a double-sided insert with its extra edges, the cutting presentation angle is 10 degrees positive as in standard round profiling inserts. Cutters for the new inserts feature coolant delivery to each individual insert, extending edge life even when running difficult stainless steel or superalloys. Insert grade choices are available to cover steel, superalloys and stainless steel.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- profiling

profiling

Machining vertical edges of workpieces having irregular contours; normally performed with an endmill in a vertical spindle on a milling machine or with a profiler, following a pattern. See mill, milling machine.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.