Contact Details

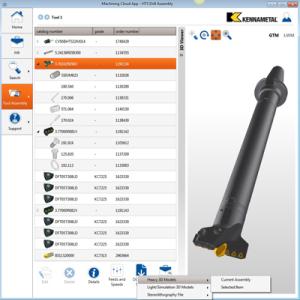

Kennametal is introducing new high-performance HSS-E-PM (powder metal) Beyond taps for large-diameter tapping. Target applications for the new tools include some of the most essential wind turbine components such as hubs, rings, and gearbox housings.

With a highly wear-resistant powder metal substrate and proprietary top layers and coatings, the new Beyond HSS-E taps provide superior performance in tapping steel components such as gear rings and mainshafts; or for tapping cast-iron components such as hubs, housing, and gear boxes. The taps are available in sizes from M24 to M42.

Designed for both conventional non-rigid and CNC-synchronous tapping machines, precision h6 shanks enable use in either conventional tap holders with square drive or in precision round toolholders. Wind energy component suppliers will want to note an extra-long version is available to reach the longer overhangs common on these large components.

"Unlike other choices on the market, the addition of these large size taps with our KSEM Plus modular drilling program provide a complete solution to drill and finish the hole," says Marcelo Campos, Senior Global Product Manager, Tapping at Kennametal. "Where most other large-size taps are specials, we're providing a broad standard range of differentiated designs and coatings for increased speeds and better tool life across a wide spectrum of applications."

Related Glossary Terms

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.