Chucks

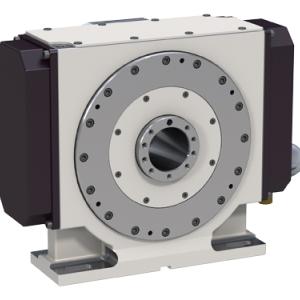

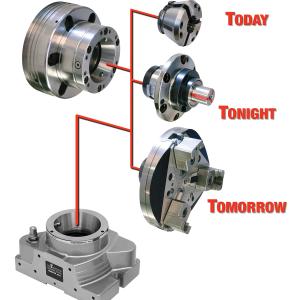

Product Focus: BIG Kaiser Mega New Baby Chucks

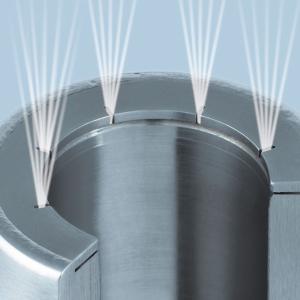

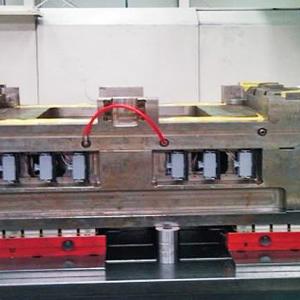

This is a video supplement to Cutting Tool Engineering's Productive Times case study titled, "Shop wrangles runout challenge," which involved BIG Kaiser Precision Tooling Inc. and Homeyer Precision Manufacturing. The Challenge: Minimize endmill runout to extend tool life when producing aluminum-based forceps. The Solution: A collet chuck that provides minimal runout. For the full Productive Times article, click here.