In their 26 years, Homeyer Precision Manufacturing has taken on some of the most demanding industries and jobs. Perhaps the most precise yet is among today’s production lineup at the company’s 63,000 sq. ft., Marthasville, Mo., shop—bipolar, aluminum-based forceps used by neurosurgeons performing brain surgeries.

In their 26 years, Homeyer Precision Manufacturing has taken on some of the most demanding industries and jobs. Perhaps the most precise yet is among today’s production lineup at the company’s 63,000 sq. ft., Marthasville, Mo., shop—bipolar, aluminum-based forceps used by neurosurgeons performing brain surgeries.

The forceps must meet exacting standards, and the machining setup had to maintain consistent precision through production runs in the thousands.

As the product gained popularity, demand from the customer grew, and so did the strain on Homeyer’s production. The setup at the time required increased monitoring after about the first 1,800 parts were produced. Because of runout, the endmill would lose its integrity and produce junk parts from part 2,200 to part 2,400, which required frequent tool changes by the operator and hampered productivity.

This wasn’t sustainable. The customer’s previous manufacturing process couldn’t keep up with demand, driving them to switch to Homeyer in the first place, and the shop wasn’t about to fall victim to a similar move.

Forceps shown, from left to right, in raw form to finished final product. All images courtesy BIG Kaiser.

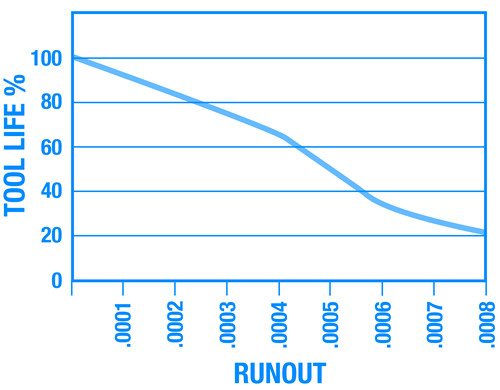

Chart shows tool life compared to runout.

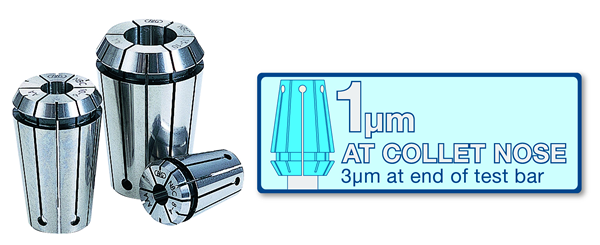

Mega New Baby Chucks from BIG Kaiser. Click here for a video showing the chucks in action.

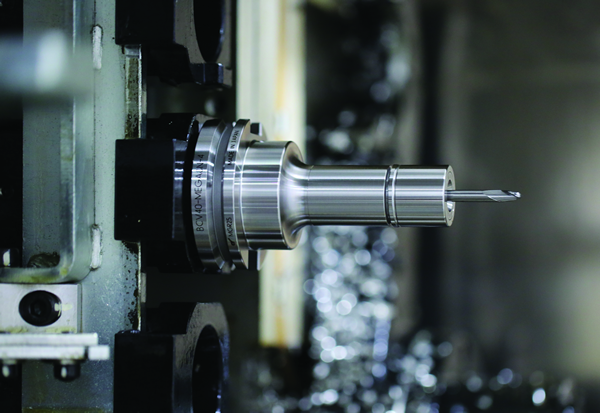

The tool holder in the magazine.

One of Homeyer’s guiding principles is to take advantage of the latest and greatest technology, but the idea for improving this process came to them in a rather unconventional way.

Herb Homeyer, who founded the shop in 1990, is chairman of the National Tooling and Machining Association (NTMA), which afforded him the opportunity to go on the organization’s European Tech Tour in February 2015. Two of the stops in Switzerland were tooling manufacturer BIG Kaiser and coolant producer Blaser Swisslube. The twin visits got Homeyer thinking about how new tooling combined with a different coolant could improve productivity.

When he returned home, Homeyer invited Blaser Swisslube and BIG Kaiser's U.S.-based vice president of sales and engineering, Jack Burley, to the Homeyer shop to discuss the medical cell that produces the forceps. After examining the setups, Burley immediately thought of his BIG Daishowa product line and the new Mega New Baby collet chuck.

What he found was the setup on the Okuma Space Center MB-5000H horizontal machining center was sound, and a Blaser coolant tailored to Homeyer’s needs. Burley was confident the holder’s BIG-PLUS dual-contact system and AA-grade New Baby collet with guaranteed TIR of less than 3µm at 4 times the diameter would improve performance of the 1/8" solid-carbide, 2-flute endmill used to machine most of the critical features on the forceps and boost productivity, economic efficiency and machining quality.

They ran a few tests with the new setup and the results were dramatic. The new holder and coolant improved tool life by 300 percent, allowing production to go unmonitored without interruption for a much longer period of time. Instead of having to keep an eye on the job at part 1,800, there was no deterioration in finish until after more than 7,000 parts were produced.

“Not only do the tools last longer, but the end product is even better,” said Tim Wetzel, general manager at Homeyer. “The holder is highly precise and accurate. The gains we’ve achieved will ensure this product stays manufactured at Homeyer, no matter how much demand grows or how quickly.”

Wetzel and the team have been so pleased with the tooling change that they’ve made the decision to use more of it in other operations. “We’ll be changing more tooling to BIG Kaiser, starting with the highest usage tools first,” he said.

“We feel once all the tooling is replaced we will be able to substantially increase our feed rates,” Wetzel said. “But, in order to maximize the potential, we need to improve our fixture and workholding. Once that’s done, we expect about a 30 percent gain in efficiency across the board.”

Contact Details

Contact Details

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- total indicator runout ( TIR)

total indicator runout ( TIR)

Combined variations of all dimensions of a workpiece, measured with an indicator, determined by rotating the part 360°.