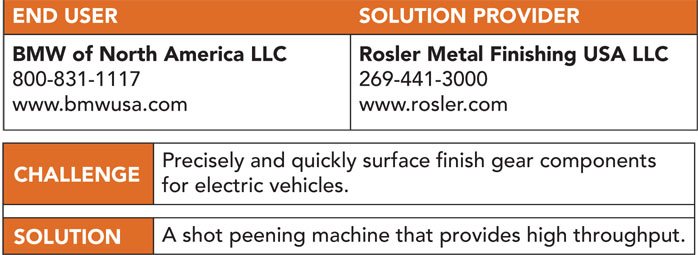

Shot peening has established itself in the automotive industry as a crucial surface refinement operation. For this finishing task, Munich, Germany-headquartered automaker BMW integrated the indexing satellite table shot blast machine RST 200-S15 from Rösler Oberflächentechnik GmbH, Untermerzbach, Germany, into a new manufacturing line for gear components for electric vehicles at its plant in Dingolfing, Germany. (Rosler Metal Finishing USA LLC is in Battle Creek, Michigan.)

The customer decided to purchase the Rösler equipment because BMW reportedly had excellent experience with machines of the same type regarding productivity, process stability and ease of maintenance.

The indexing satellite table shot blast machine RST 200-S15 from Rösler is for shot peening different gear components in short cycle times. Rösler Oberflächentechnik

The indexing satellite table shot blast machine RST 200-S15 from Rösler is for shot peening different gear components in short cycle times. Rösler Oberflächentechnik

In the automotive industry shot peening is utilized to induce a compressive residual stress in gear components, for example, and thereby extend the lifespan of the material. For this task, the BMW plant uses satellite table shot blast machines from Rösler, which have been precisely adapted to the customer’s technical requirements. As a result, the highly adaptable RST 200- S15 equipment concept was implemented in the new manufacturing line for gear components.

Rösler reports that the rotary table of the shot blast machine contains 15 rotating satellite stations equipped with workpiece specific fixtures. Depending on the workpiece, a part loading/unloading system supplied by the customer places one or several workpieces on the satellite stations. After they have been loaded, the workpieces pass through multiple stations in the shot blast machine at indexing cycles of 20 seconds.

These stations include two blast positions. Special lifting gates prevent spillage of blast media into other stations. During the peening operation the satellites rotate at preset speeds in front of the blast turbines. In combination with the automatic blast pattern adjustment to the respective workpiece shape, this achieves homogeneous peening results. A compressed air cleaning station placed in front of the loading/unloading section blows off dust and residual blast media from the finished components.

Selection of the workpiece-specific processing programs, including the setting of the turbine position and blast pattern, is handled by the master computer of the manufacturing line. For this purpose, the controls of the peening machine were integrated into the upper-level computer system at the Dingolfing plant.

To safely achieve the peening results — as defined by predetermined Almen values — within the specified cycle times, the machine is equipped with two high-performance blast turbines, Model Rutten Gamma 400 with a drive power of 22 kW for each turbine. The special “Y” design of the throwing blades with their precisely calculated curvature guarantees a precise media acceleration with maximum throwing speed, producing excellent operational efficiency, according to Rösler. Compared to conventional turbines, this design lowers energy requirements by about 25%. Another significant benefit of this design is that both sides of the throwing blades can be used.

The rotary table contains 15 rotating satellite stations equipped with workpiece-specific fixtures. A special automatic workpiece handling system supplied by the customer places and removes the workpieces onto and from the satellite stations. Rösler Oberflächentechnik

The rotary table contains 15 rotating satellite stations equipped with workpiece-specific fixtures. A special automatic workpiece handling system supplied by the customer places and removes the workpieces onto and from the satellite stations. Rösler Oberflächentechnik

To meet the high standards in the automotive industry regarding process stability and traceability of the manufacturing processes, the controls of the shot peening machine allow the continuous monitoring of all relevant shot blasting parameters. This includes the control of the turbine and satellite rpm, the blasting time and the thrown blast media quantity. Replenishment of the blast media takes place fully automatically.

Another key advantage of the shot peening system is its excellent wear protection and ease of maintenance, Rösler reports. The machine housing is made from manganese steel, and the immediate blast area is additionally protected with easily exchangeable protective plates made from highly wear-resistant material. The turbines are made of specially formulated high-strength alloys, which offer a 16 times longer usable life of all major turbine components.

Quick and easy accessibility to all maintenance and service points of the shot peening machine are another key feature of the RST 200- S15. The turbines are mounted on doors that can be easily swung out. This facilitates maintenance work on the turbines — for example, turning of the throwing blades — and allows easy access to the blast area for exchanging the protective wear plates. Along with the control panel, the machine sections for blast media transport and cleaning can be easily reached through the large inspection and maintenance platform.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- peening

peening

Mechanical working of a metal by hammer blows or shot impingement.

- residual stress

residual stress

Stress present in a body that is free of external forces or thermal gradients.

- shot peening

shot peening

Cold working a metal’s surface by metal-shot impingement.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.