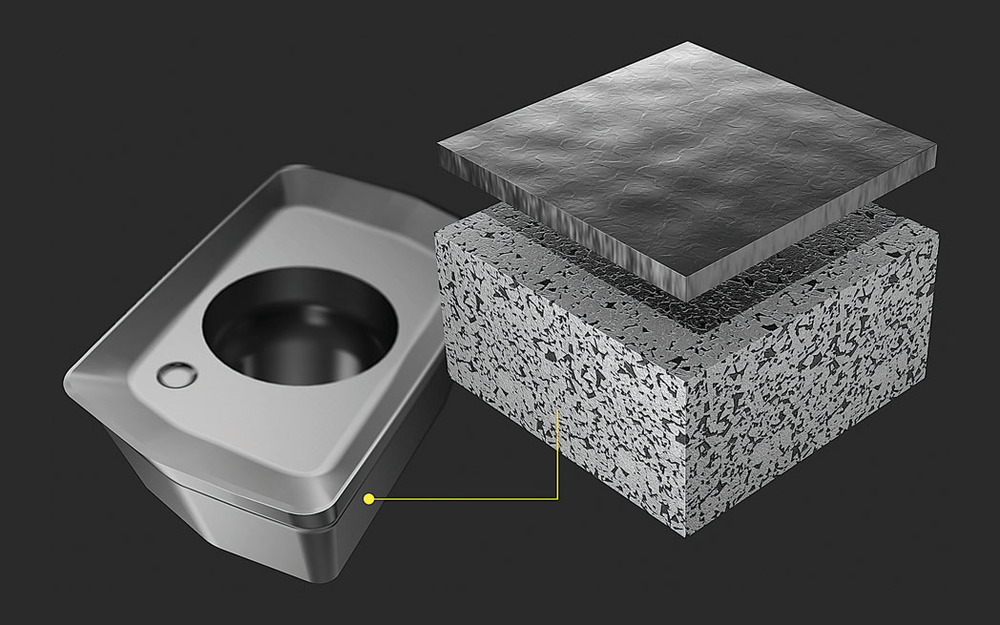

According to eifeler, the company takes a performance-focused approach to coating tools, ensuring the optimal synergy between the substrate, coating and application. voestalpine eifeler

Because a coating resists the heat a cutting tool faces at the tool/workpiece interface during machining while reducing friction and wear and potentially serving as a wear indicator, the majority of cutting tools are sold coated. The exact percentage is difficult to establish but probably at least 60% are coated, with physical vapor deposition being the dominant deposition process.

Determining the appropriate coating or combination of multilayered coatings for an application requires a tool coating company to consider an array of factors, including the workpiece material, the common failure mechanism, the machining parameters, edge preparations, and the tool material, type and size, said Jeff Barlow, president of CemeCon Inc. in Big Flats, New York, which offers services for coating inserts and round tools and sells PVD and diamond coating systems. “We don’t just slap a coating on somebody’s tool and say it should be good enough. We optimize it.”

The process starts with the material being cut, Barlow noted. “From there it’s determining how the tool is going to be used to determine the coating and thickness that makes the most sense.”

On the PVD side, the thickness can range from less than 1 μm to 12 μm (0.00004" to 0.00047"), and on the diamond side from 3 μm to 18 μm (0.00012" to 0.00071"), he said. To prepare a tool for coating, CemeCon pretreats and cleans the substrate to align with the specific needs of the customer and cutter. The company primarily serves cutting tool manufacturers, and about 95% of the tools it coats are made of carbide, with the remainder being HSS.

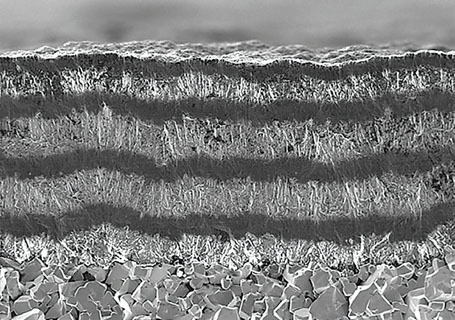

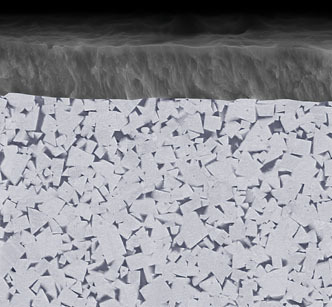

Coated tools have a long history that dates back to the bronze-coated tools of ancient Egypt, with the coating of industrial cutting tools starting in the 1960s. A more recent development for depositing PVD coatings is high-power impulse magnetron sputtering (HiPIMS), which CemeCon launched in 2016, said Ryan Lake, sales manager. With the dense and fine grain morphology coating structure that HiPIMS deposits, CemeCon increased both the coating hardness and toughness over its legacy technologies. “Traditionally, if you increase hardness, you decrease toughness and vice versa.”

Lake added that almost any material in the periodic table can be sputtered to create coatings with a wide variety of chemical compositions. In addition, the coating has a smoothness that is inherent in sputtering to reduce the friction between the workpiece material and tool and maintain a sharp cutting edge.

CemeCon offers PVD tool coatings deposited with a HiPIMS system and patented diamond coatings that combine the advantages of microcrystalline and nanocrystalline layers to slow crack formation. CemeCon

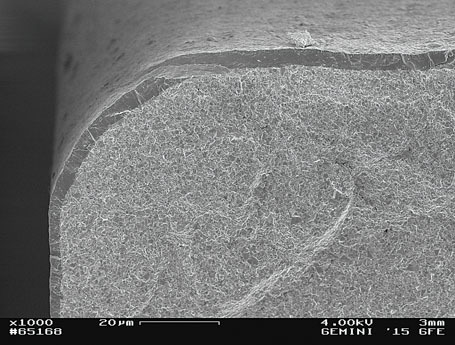

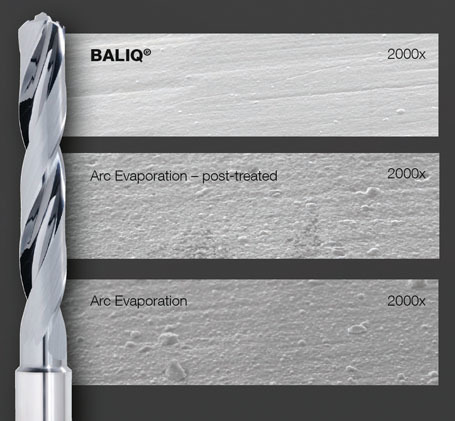

A BALIQ-coated tool enables smooth chip removal and eliminates the need for mechanical post-treatment, according to the company. Oerlikon Balzers

A benefit of the company’s CCDia series diamond coating materials is the coatings combine the advantages of microcrystalline and nanocrystalline layers to slow crack formation by alternating the application of both layer variants and producing a coating with enhanced adhesion and smoothness, Barlow explained. “If it was a single form of diamond, one structure or the other, once a crack is formed it would go down to the substrate quickly. The intent is to slow that crack by changing the structure of the coating every step you go.”

Sales of coating equipment have become a significantly larger part of CemeCon’s business in the U.S. and globally since it introduced HiPIMS, Lake said, such as the CC800 HiPIMS production system. The system can handle all existing CemeCon coatings and almost all other PVD coatings on the market, the company reports, and it coats at a rate of up to 2 μm/hour in pure HiPIMS mode with capacity levels of up to 1,800 shank tools or 5,000 inserts. “One of the biggest advantages is the fast process times. The tools are only in the chamber a limited amount of time.”

Lake said CemeCon put a premium price on its HiPIMS PVD coatings, but performance offset that premium to the point that customers adopted them quickly and “told us we had something special. We were increasing tool life upwards of 30% over our legacy coatings, and we were already competitive in the marketplace. This is why we have decided HiPIMS is our foreseeable future for PVD technology.”

A Smooth Combination

Oerlikon Balzers Coating USA Inc. in Schaumburg, Illinois, is another provider of advanced HiPIMS coating technologies and equipment solutions. “Our S3p technology enables the application of a wide range of high-performance coatings using the HiPIMS process,” said Yong-Tae Jeong, head of customer solution centers, Americas. S3p stands for Scalable Pulsed Power Plasma, which combines the advantages of the arc evaporation and sputtering technologies.

A technician loads tools into a high-power impulse magnetron sputtering (HiPIMS) PVD coating machine from CemeCon. CemeCon

In arc evaporation, a high electrical arc moves on the surface of a target, the target material immediately melts, and the metal vapor condenses on the workpiece. Arc evaporation provides a high degree of ionization, which is beneficial. Because of the explosive nature of the conventional arc evaporation process, droplets (macroparticles) of metal are formed, which may cause a rough coating surface, according to the company.

The S3p process prevents droplet formation. Sputtering is a process whereby atoms are ejected from a solid target material due to bombardment of the target by energetic ions, Oerlikon Balzers states. In a thin-film coating, this is achieved by accelerating argon ions towards a solid target where they knock out metal atoms that are collected on the workpiece.

By combining the two technologies, the S3p process reportedly produces a smooth coating surface, enhanced adhesion and a high coating density and hardness. The smooth surface means built-up edge is reduced even when cutting difficult-to-machine materials.

By generating a smooth surface, mechanical post-treatment of coatings is eliminated, Jeong said, saving money and improving throughput. Based on the S3p technology, Oerlikon Balzers introduced the BALIQ family of wear-resistant coatings. The density of the coatings is very close to the highest density theoretically possible to provide a high resistance to crack propagation, according to the company.

High-Energy Vaporization

For extreme and high-performance applications, as well as the growing performance expectations in standard machining operations, voestalpine eifeler Coatings North America in Elgin, Illinois, offers an array of PVD and diamond-like coatings (DLC) and PVD and diamond-like coating systems, said Sergio L. Rodrigues, global brand manager. The company employs advanced arc PVD technology to deposit coatings. The technique uses high-energy arc sources to vaporize target materials, which are then ionized and deposited as dense, strongly adherent coatings on the tool surface.

The high level of ionization enhances coating adhesion and hardness, he added, while the refined process control allows for consistent quality and reproducibility across batches. “Our arc PVD systems are engineered to significantly reduce the presence of macroparticles, enhancing surface smoothness and cutting performance.”

Sandvik Coromant states that its new Zertivo 2.0 multiple-layer PVD coating is a standout feature of the company’s CoroMill Plura barrel cutter for profiling, delivering significantly longer tool life by reducing wear and improving heat resistance. Sandvik Coromant

The company’s flagship PVD coating developments include the Sistral-Gold nanostructured coating for difficult-to-machine metals, Sublime for gear cutting and Arduro for machining metals harder than 55 HRC. Rodrigues noted that Sistral-Gold has a hot hardness up to 900° C (1,652° F), Sublime has a hardness of 3,300 HV and thermal resistance up to 1,100° C (2,012° F), and Arduro integrates exceptional toughness with high hardness to withstand thermal and mechanical stresses when dry cutting. The coatings are deposited with the alpha440P production-ready PVD system.

For applications that require extremely low friction and high temperature stability, Rodrigues said eifeler also offers DLC coatings using sputtering technology via its alpha400C system. The system produces friction- reducing coatings like Carbon-X at a temperature of less than 250° C (482° F) with fast cycles, high plasma density and easy operation. Carbon-X is for machining nonferrous metals and provides thermal stability to 400° C (752° F).

The coating selection process is application-and material-driven, he noted, as eifeler’s technical recommendation is based on a multiple-factor analysis that includes the hardness, abrasiveness and thermal conductivity of the workpiece material, the machining parameters, tool geometry and substrate, observed tool wear mechanisms, and whether or not coolant is used. “This performance-focused approach ensures the optimal synergy between substrate, coating and application, maximizing tool life and productivity.”

Prior to coating, plasma etching and sputter cleaning remove oxides and contaminants while activating the tool surface for enhanced bonding, Rodrigues explained. Tailored interlays, such as titanium- or chromium- based ones, create a gradual transition in lattice parameters and thermal expansion between the substrate and coating. In addition, high-energy bombardment ensures mechanical interlocking and densification, reducing residual stress and enhancing the load-bearing capacity at the coating/substrate interface.

“The result is exceptionally high adhesion strength, even on complex tool geometries or challenging substrate materials,” he said.

Toolmaker's Perspective

Sandvik Coromant Co. uses commercially available PVD vessels to coat its cutting tools, as well as some that the toolmaker’s PVD coating engineers developed, said Matthew Stewart, product manager for indexable milling and drilling products.

The Mebane, North Carolina-headquartered company’s latest PVD coating is Zertivo 2.0, which was released in March, he noted. The new coating complements the Zertivo 1.0 PVD coating by targeting round tools while the coating introduced in 2016 is more for milling products.

For example, the CoroDrill Dura 462 solid-carbide drill has a multilayer TiAlCrSiN Zertivo 2.0 coating, Steward said. The thickness of a multiple nanolayer coating depends on the application, such as how much heat resistance is needed. “With the nanolayers, they are basically small layers like sheets of paper that are stacked up.”

That drill is available in a diameter up to 20 mm (0.787") and a micro range from 0.03 mm to 3.0 mm (0.0012" to 0.118"). Because of their small size, microdrills are fragile and require better care and handling when moving them in and out of a PVD furnace compared to the macro drills, Stewart said.

Sandvik Coromant’s Zertivo coating on the substrate of a milling insert. Sandvik Coromant

Sandvik Coromant’s Zertivo coating on the substrate of a milling insert. Sandvik Coromant

Inside a furnace, microtools under 3 mm in diameter pose several critical challenges that require specialized expertise and technology, Rodrigues explained. To start, they have high aspect ratios with long, slender geometries that make it difficult to achieve a uniform thickness. Also, the coatings must enhance wear resistance without compromising the delicate geometries that are critical for cutting performance. Lastly, the low thermal mass of microtools makes them highly sensitive to thermal distortion and layer thickness variation.

He said eifeler has developed and optimized ultrafine PVD coatings for microtools, including TiN-ultrafine, TiCN-ultrafine and Sistral-ultrafine. “These coatings are applied using modified arc PVD processes with advanced plasma control, enabling reduced coating thickness, typically below 2 μm, enhanced adhesion and excellent surface smoothness.”

Lake said CemeCon sees significant growth in the microtool market in the U.S. and especially overseas. “That is an area where sputtering has excelled and HiPIMS even more so.”

Oerlikon Balzers also targets microtool applications, Jeong said. “Whatever the coating type is, we recommend using the S3p version for microtools.”

While cutting tool manufacturers continue to invest in coating equipment and R&D to develop new coating chemistries and recipes, and Sandvik Coromant even makes special grades and coatings for specific applications, Stewart said he has not seen any tool customers with their own coating vessels. “We see a couple of regrinders that have vessels that do some TiN and TiAlN, some very common coatings.”

Some high-volume OEMs explore in-house coating, but Rodrigues said eifeler strongly recommends that the company’s coating centers perform the task because of their deep application knowledge, process stability and repeatability, access to the latest coating technologies and upgrades, and fast turnaround times.

However, as end users continue to realize the advantages of inhouse tool production to gain control of the process, Lake said more end users are doing so. “We are seeing growth in that area on our coating service, and, by extension, more end users are becoming interested in in-house coating.”

He noted that as CemeCon continues development on HiPIMS technology, processes and chemical compositions will change, but coatings will be deposited using the current platform as it stands

A Tool Life Extension

Just because a round tool is worn doesn’t necessarily mean it is ready for the scrap or recycling bin. Tool coating companies and toolmakers typically regrind and recoat cutters. Oerlikon Balzers Coating USA Inc. is one such company. “We provide regrinding and recoating for the customer,” said Yong-Tae Jeong. “We can do it more than several times.”

As long as tool wear or chipping is not excessive and the tool is not below a minimal tolerance, Stewart said Sandvik Coromant Co. advertises that a round tool, such as a drill, can be reground and recoated three times. “Usually, our drills are in an H9 tolerance for hole size. As long as you get three regrinds, we say you can still stay in that hole tolerance of H9.”

On the other hand, Stewart recommends returning worn inserts to the manufacturer. “We can break them down into their fine elements and recycle those and put those back into new inserts.”

Other coating companies, such as CemeCon Inc. and voestalpine eifeler Coatings North America, only focus on their specialty. “We do not do any regrinding in-house, but we do recoat tools that have been reground by our customers,” said CemeCon’s Ryan Lake.

While offering recoating services, typically from three to five times per tool, eifeler also does not perform regrinding, said Sergio Rodrigues. “Our recoating processes include precise de-coating, surface preparation and reapplication using the same advanced PVD technologies, ensuring consistent performance across the tool’s lifecycle.”

—Alan Richter

contributors

CemeCon Inc.

607-562-2363

www.cemecon.com

Oerlikon Balzers Coating USA Inc.

847-619-5541

www.oerlikon.com/balzers/us/en

Sandvik Coromant Co.

800-726-3845

www.sandvik.coromant.com

voestalpine eifeler Coatings North America

630-587-1220

www.eifeler.com/northamerica

Related Glossary Terms

- Vickers hardness number ( HV)

Vickers hardness number ( HV)

Number related to the applied load and surface area of the permanent impression made by a square-based pyramidal diamond indenter having included face angles of 136º. The Vickers hardness number is a ratio of the applied load in kgf, multiplied by 1.8544, and divided by the length of diagonal squared.

- built-up edge ( BUE)

built-up edge ( BUE)

1. Permanently damaging a metal by heating to cause either incipient melting or intergranular oxidation. 2. In grinding, getting the workpiece hot enough to cause discoloration or to change the microstructure by tempering or hardening.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- coated tools

coated tools

Carbide and high-speed-steel tools coated with thin layers of aluminum oxide, titanium carbide, titanium nitride, hafnium nitride or other compounds. Coating improves a tool’s resistance to wear, allows higher machining speeds and imparts better finishes. See CVD, chemical vapor deposition; PVD, physical vapor deposition.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- physical vapor deposition ( PVD)2

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- process control

process control

Method of monitoring a process. Relates to electronic hardware and instrumentation used in automated process control. See in-process gaging, inspection; SPC, statistical process control.

- profiling

profiling

Machining vertical edges of workpieces having irregular contours; normally performed with an endmill in a vertical spindle on a milling machine or with a profiler, following a pattern. See mill, milling machine.

- residual stress

residual stress

Stress present in a body that is free of external forces or thermal gradients.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

- titanium nitride ( TiN)

titanium nitride ( TiN)

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.