Custom tooling solution solves legacy part challenges

Custom tooling solution solves legacy part challenges

Tri-Tec Manufacturing designs and builds remote actuation assemblies such as vent valves and actuators, used aboard U.S. Navy ships. The parts are often installed in critical safety systems like flood boundaries and must withstand demanding conditions. These ships typically stay in service for decades, which, due to their longevity, can create challenges for the Kent, Washington-based manufacturer when they service these legacy parts.

Tri-Tec Manufacturing designs and builds remote actuation assemblies such as vent valves and actuators, used aboard U.S. Navy ships. The parts are often installed in critical safety systems like flood boundaries and must withstand demanding conditions. These ships typically stay in service for decades, which, due to their longevity, can create challenges for the Kent, Washington-based manufacturer.

This is especially the case when the original tooling used to create the part is no longer supported by the vendor. That was the case when they received a Navy actuator housing for repair. The job called for re-machining a critical surface deep inside a bronze casting, accessed through a narrow hole. It was a long-serving part, but the previous tools weren't available. They needed a viable solution, and they found it from Heule Precision Tool.

"Ships have 40, 50 year lives, so a lot of things we do, we're going to keep doing down the road," said Mark Smith, lead manufacturing engineer at Tri-Tec. They support ongoing repair work and maintain critical components throughout the life of the fleet. Sometimes, they have to rework a decades-old part, and they're constantly addressing new challenges as tools and technology evolve. "We have more than 20,000 unique part numbers," Smith said, "but often, our orders will be 10 or 15 parts. We're almost like a job shop in that way."

From first job to new designs

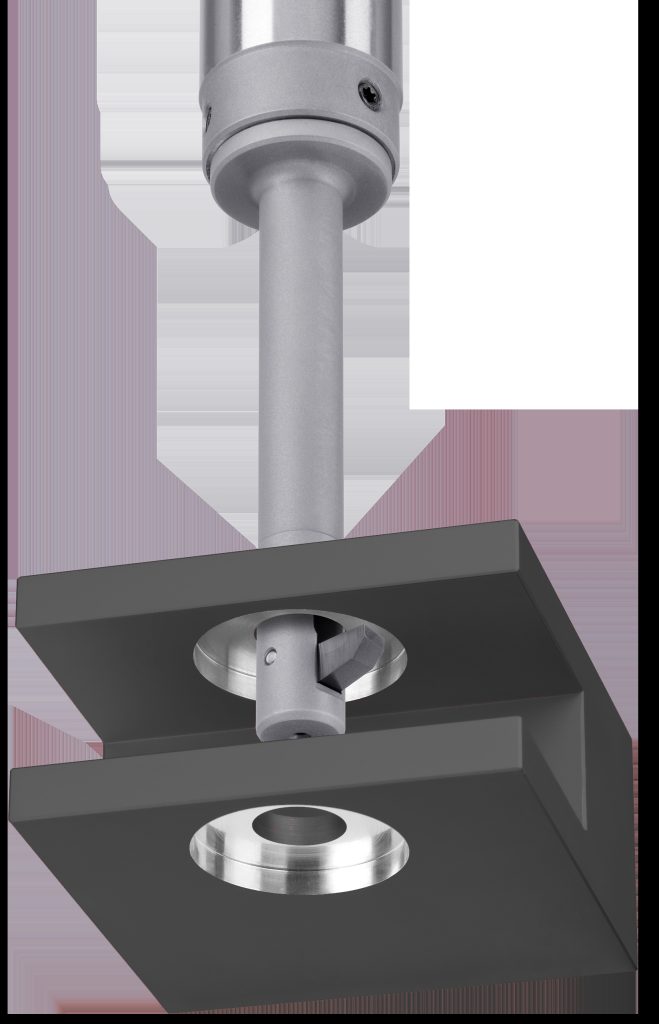

Tri-Tec first purchased a B series 11mm back spot facing tool (BSF) tool for a Navy repair application to replace an unsupported indexable back spot facing tool where the insert was no longer available. This tool is currently being used in production for a long-established design part.

However, as new development projects arose, given their success with Heule back boring products, they purchased an A series BSF-A-650/040-7.0 with BSF-M-A-1A-6.0) to do the .520" diameter BSF for a "brand new" development project's version 1 prototype. This tool was used for a part that presented challenging, interrupted cut conditions. Ongoing support from Heule provides a bridge between Tri-Tec's older applications and new developments, helping them continue to serve clients with effective solutions.

Precision work in tight spaces

All Tri-Tec's parts must meet the Navy's performance and durability standards. The actuator housing being prototyped in this case was made from manganese bronze (C86300). Inside the casting, four raised mounting pads needed to be machined with smooth, flat surfaces to support a transformer. These back spot faces needed to be cut from inside the housing, through a 0.257-inch access hole, to a finished diameter of 0.520 inches. One face was right up against a raised boss, creating an interrupted cut and leaving little room to work.

In the past, Tri-Tec used a similar indexable back spot-facing tool for this type of work. The tool had a small shank that could pass through a hole and expand to cut on the far side. It was a setup that had worked for years, but the insert line was discontinued by the manufacturer. Even if it had still functioned, the tool's limited diameter range wouldn't have worked for the larger spot facing they needed.

With no way to repeat the original process, the team needed a new, supported solution that could meet the same specs and remain available for future repairs.

Smith had previously worked with Heule on a job involving silicon brass housing for fiber optic cable mounts. When the actuator housing presented this new set of challenges, he knew where to turn.

Smith worked with Matt Clark of Clark Manufacturers, Heule's local representative, to evaluate the part's geometry and cutting requirements. Together, they selected the Heule back spot-facing tool (BSF-A-0650/040-7.0) that could reach through the 0.257-inch hole and cut a clean 0.520-inch flat on the far side of the part. No additional fixturing was needed to use the BSF tools.

The only process change, compared to the obsolete tool, was to rough drill the through hole to match the BSF tool, then open it up to final size after the BSF tool cut the part. Heule tools feature retractable cutter mechanisms, so the blade expands inside the part and retracts after the cut is complete.

This eliminates the need for custom fixturing or multi-step setups while preserving accuracy and surface quality. The interrupted cut path caused by the raised boss required some adjustments. Smith said the team tuned their feeds and speeds to stabilize the tool path in order to complete the cuts successfully.

"It proved to be problematic just because of the nature of the casting and the interruption, but once we dialed in on what we were doing there, it worked flawlessly," he said.

Only two housings were prototyped before the part was redesigned, but Smith said the new layout may still include internal machining features. More importantly, the success of this prototype job opened the door for future applications.

Tri-Tec now uses the same tool setup to remanufacture other parts that were originally produced decades ago. Smith emphasized the importance of having tooling that remains available and supported long after the original job is complete, even for small batches.

"We may only make a few of something, but we need the tools and process to work every time," Smith said. "Especially in Navy work, these parts don't just go away. They come back in for repair, even decades later." In industries like defense and shipbuilding, parts often come back years later for refurbishment.