Contact Details

Kennametal has developed a 3D-printed stator bore tool to meet growing customer demand for lighter weight tooling solutions used to machine components for hybrid and electric vehicles. E-mobility components are typically machined on small, low-horsepower CNC machining centers that require lighter weight tooling solutions. Kennametal’s 3D printed stator bore tool weighs half that of the conventionally manufactured version, while still meeting accuracy, roundness and surface finish requirements for aluminum motor body boring.

“The main bore, that houses the stator of an electric motor measures approximately 250 mm in diameter (9.84") and approximately 400 mm (15.74") in length, with a smaller bearing bore at the bottom,” said Harald Bruetting, manager, program engineering. “When manufactured using conventional means, a reamer for this type of application would weigh more than 25 kilograms (55 lb.), far too heavy for the existing machine tool or for an operator working with the tool.”

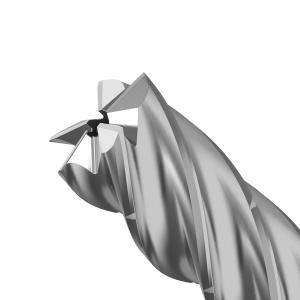

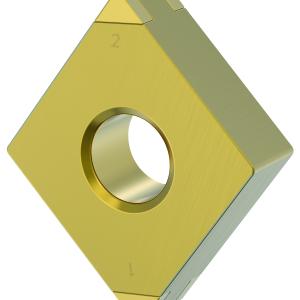

Bruetting and Kennametal’s Solution Engineering Group turned to the company’s in-house additive manufacturing capabilities to 3D-print a strong but lightweight indexable tool, equipped with proven Kennametal technologies, including fine adjustable RIQ reaming inserts for high precision finishing and a KM4X adaptor for maximum rigidity. The tool also features internal 3D-printed cooling channels that help maximize productivity and tool life.

“By using metal powder bed 3D-printing together with finite element analysis software, we were able to design and build a tool that brought the moment of inertia very close to the spindle face, increasing its rigidity while meeting the customer’s weight restrictions,” said Werner Penkert, manager, future solutions. “It is an excellent example of how Kennametal is using advanced manufacturing technology to help meet our customer’s unique challenges.”

Two versions of the tool were built, one with a carbon-fiber tube, the other using a 3D-printed metal tube. The results were impressive. The tool with the 3D-printed tube weighed in at 10.7 kg (23.6 lb.) and the carbon fiber version at 9.5 kg (20.9 lb.), less than half of their conventional counterparts.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.

- reamer

reamer

Rotating cutting tool used to enlarge a drilled hole to size. Normally removes only a small amount of stock. The workpiece supports the multiple-edge cutting tool. Also for contouring an existing hole.