Contact Details

Iron’s everywhere. The turbines in those big windmills popping up all over the place. Engine blocks, transmission cases, and turbocharger housings. The pumps that bring water to our faucets and the hydraulic manifolds that put the “move” into earthmoving machinery. Without iron, none of these would be possible. This is why Kennametal has produced cutting tools that make iron machining both cost-effective, efficient, and ensures easy handling.

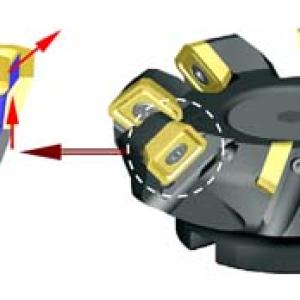

One significant step in this direction came a little over one year ago, when Kennametal announced its Mill 16 facemill, the next generation in roughing tools designed specifically for removing large amounts of cast iron quickly, offering the highest productivity and lowest cost per edge in roughing and semifinishing applications.

Kennametal announces that it is building on that success by expanding the Mill 16 platform by introducing new cutter body styles, new insert geometries and grades, and a split case design for large diameter bodies that reduces spindle bearing loads. With these new additions the portfolio will fit any of your cast iron face milling applications. From fine pitch wedge style cutters for highest productivity and very powerful machines to medium and coarse pitches screw-on cutters when horsepower is limited. From machining of small components to very large components.

The Mill 16’s new split case design meets truly massive machining needs, with wedge-style cutter bodies ranging from 300 to 500 mm (12 to 20 in.) in diameter. And for those worried about hanging such humungous cutters off their machine spindles, there’s good news: the largest split case Mill 16 cutter body weighs only 20.4 kg (48.45 lb.), roughly one-third that of competing designs, but still able to rotate at up to 2,800 rpm (almost 15,000 sfm).

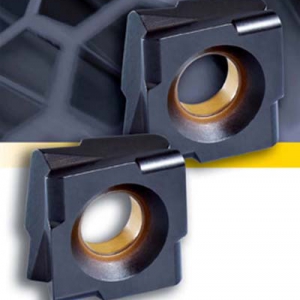

And there is even more good news. All cutters use the same innovative, multi edged design insert. An insert with 16 cutting edges that provides lowest cost per cutting edge.

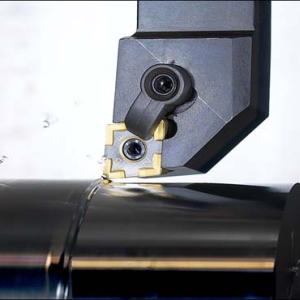

The Mill 16 product line is covering all heavy roughing and semifinishing applications. But what

about finishing of cast iron? To an engine manufacturer, flatness and finish is everything. Without it, leaks are sure to occur, leading to expensive warranty claims and unhappy customers. The same can be said for those making transmissions, hydraulic manifolds, pump bodies, and anywhere a smooth sealing surface is needed. Unfortunately, the material used to make many of these components—cast iron—can be challenging to machine.

There are many options available on the market for fine finishing of cast iron these days. And most of them can achieve the required surface finish. \But to keep it consistent is a different story. And that is one of the pain points for many customers. To have a consistent, reliable process when it comes to fine finishing of cast iron. The deterioration of the finishing occurs as soon as the inserts show slight wear. That causes an increase in cutter pressure, resulting in vibration, and feeding marks are observed. The result is downtime due to frequent insert exchange.

The super positive KCFM – Kennametal Cast Iron Finishing Milling - with the new KBK50 full top PCBN (polycrystalline cubic boron nitride) grade was developed to address these issues. Now customers can produce much more parts per edge in a reliable and consistent manner, so the cost per component will decrease, according to the company.

And keep in mind machining time reduces drastically since PCBN can be applied with three times higher cutting speeds compared to carbide inserts.

Combining the semi finishing KY3500 silicon nitrate ceramic with KBK50 finishing wiper inserts is also a productive, and cost-effective solution for customers that don’t want to have a full load PCBN inserts in the cutter.

PCBN and ceramic grades are perfect for mass production and stable conditions. But in many cases there is also the need for fine finishing on rather unstable conditions, such as weak workpiece clamping, limited spindle speed, long overhang, or when tooling cost is the primary consideration.

The answer to that the carbide grade KC514M. A TiAlN PVD coating that is both tough and wear resistant. Designed for light to medium machining. KC514M can be applied with or without cutting fluids.

Related Glossary Terms

- facemill

facemill

Milling cutter for cutting flat surfaces.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- polycrystalline cubic boron nitride ( PCBN)

polycrystalline cubic boron nitride ( PCBN)

Cutting tool material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder. PCBN is available either as a tip brazed to a carbide insert carrier or as a solid insert. Primarily used for cutting hardened ferrous alloys.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

Additional Products from Kennametal Inc.

Pagination

- First page

- Previous page

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9