Contact Details

Tool selection, tool configuration, and the best applicable tooling advice based on the customer's part and process requirements are all at the touch of a few mouse clicks in Kennametal's revolutionary NOVO. CAD models, complete assembly lists, automated job report functionality and much more all promise new levels of process planning efficiency.

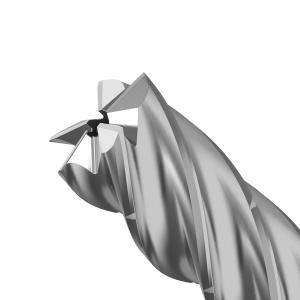

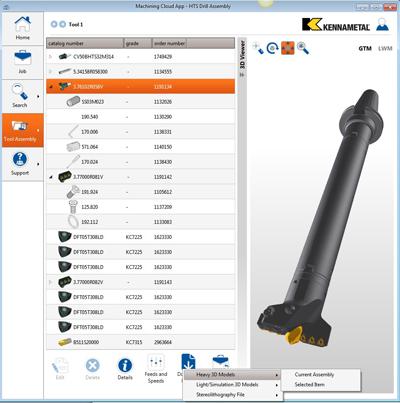

Here, a model of an HTS Drill Assembly is shown with all associated inserts, adaptors, and spare parts. NOVO accomplishes in minutes what formerly took hours and yields an optimized solution backed by Kennametal expertise, every time.

In a revolutionary development designed to address the critical need for improved productivity and process knowledge for manufacturing companies, Kennametal is launching NOVO, a new set of digital tools that promises far-reaching improvements in manufacturing efficiencies.

"This is a huge leap beyond simply providing a digital version of the tool and its physical properties," says John Jacko, VP and Chief Marketing Officer at Kennametal. "With NOVO's embedded intelligence in application engineering and process planning, Kennametal and our partners are opening the path to a completely connected digital art-to-part-to-profit process. NOVO is a big step in bringing such a vision to reality."

Online catalogs and tool selectors have become common options for manufacturers looking for the latest tool solutions for their production process. NOVO goes far beyond the concept of the online catalog by integrating the application engineering and production experience of Kennametal's 75-year history.

"This is the true integration of our knowledge with our customers'," says Francois Gau, Vice President, Strategic Marketing and New Business Development. "Simply put, NOVO is a process enabler, a true digital assistant with data-rich machining strategies that starts working from the moment you receive a parts drawing. With a refined and intuitive tool advisor, tool selector, and tool configurator, everything down the line gets more efficient, from parts quoting through programming, presetting, and production. The result is the absolute assurance you have the right tool to do the job."

NOVO is process knowledge delivered via the Machining Cloud. It stands alongside such web-available solutions as MTConnect for data gathering and ISO 13399 for standardizing tool data. NOVO solves many challenges for process planners, manufacturing engineers, and those who want the most efficient machining strategies based on the features of their parts. Customers are able to access NOVO via a PC application and tablet solutions coming later this fall. With the click of a button, the user will have access to all of the knowledge from more than 50,000 branded Kennametal products to achieve a more productive solution in a fraction of the time spent searching catalogs.

"NOVO works like a process planner," explains Thomas Long, head of the newly formed Virtual Machining RDE department at Kennametal. "It works from the feature back to the machining strategy and then finds the best tools for each strategy. In addition, each project is tied to application data gleaned from Kennametal's experts and decades of experience. Search for a specific Kennametal part and you also get models and all associated inserts, adaptors, and spare parts. Not only does it accomplish in minutes what formerly took hours, it yields an optimized solution, backed by Kennametal expertise, every time."

Facing ever-increasing demands for productivity and efficiency, manufacturing technology providers have responded with computer-driven machine tools, digital-based computer-aided design and manufacturing software (CAD/CAM), and significant advances in tooling. Yet one major barrier threatens this scenario: a significantly widening skills gap as older workers retire and new workers fail to engage in manufacturing careers.

"To effectively bridge the skills gap for our customers, we have developed this innovative platform to distribute the collected knowledge of Kennametal," says Gau. "More than a catalog, NOVO brings users into a community, harnessing all ongoing expertise, and providing fast access to best-in-class process knowledge. The result empowers users by providing the right solutions specifically tailored to their operations. It solves problems instead of managing data."

The vision for NOVO is to be integrated with major CAD/CAM packages and machine tool CNC controls, so designers or programmers will have instant access to Kennametal knowledge at the touch of a button without having to leave their function. "NOVO means new way of doing things, the ability to get information quickly combined with the best strategy on how to use it," Gau says.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided design ( CAD)2

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.