Loc-Jaw and Loc-Down

Loc-Jaw and Loc-Down

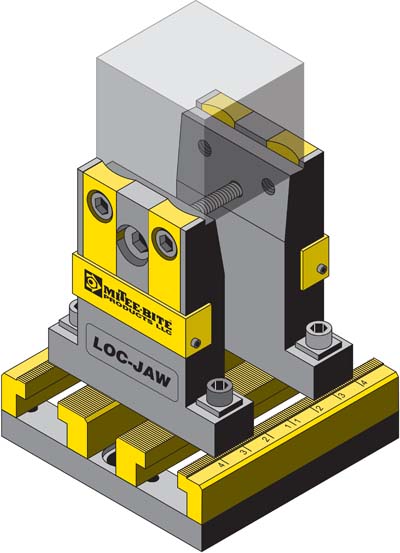

Mitee-Bite Products LLC's Loc-Jaw System for 4th and 5th axis machining requires no material preparation.

Mitee-Bite Products LLC's Loc-Jaw System for 4th and 5th axis machining requires no material preparation. The rails and gripper towers are serrated to provide a solid and easily adjustable clamping range of 0.5" to 4.0". The low profile grippers hold on only .100", allowing full access to all work surfaces including the bottom face. The base is designed to easily adapt to most machine tables with a precision bore provided for a centering disk.

A single support bolt is used to reinforce the gripper towers for rigidity and increased workholding capacity is best described as a "headless bolt" with a simple ball-lock mechanism. Primarily designed to quickly locate and secure large aerospace parts for high speed machining applications.

The Loc-Down System can also be a simple low cost solution for quick-changing fixtures on tombstones and pallet changers. The Loc-Down System is very user friendly requiring only a drilled and tapped hole (½-13 or M12) in the base plate and a drilled hole with an internal groove machined on the workpiece. Custom bushings will be available for mounting fixture plates. The Loc-Down saves the time required to completely remove a hold down bolt with less tooling interference.