Workholding is a critical component of any reliable machining setup. Poor workholding can lead to longer setup and cycle times, increased scrap and tool wear, and more rework. It was just such a scenario that prompted John Robinette, owner of United Machine Company, to shop for alternative workholding options that would ensure consistency and quality in the components it manufactures for the aerospace industry.

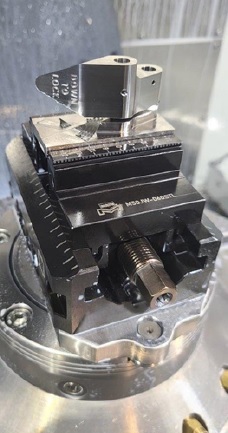

Robinette had experienced recurring issues with his previous workholding—broken jaws, part lift and rising perishable costs. After researching workholding solutions offered by Mate Precision Technologies, Robinette said what caught his attention was the DynoGrip™ vise featuring quick-change jaws, tool steel construction and an advertised repeatability of 0.0004" (0.010mm). So he purchased one and, using his Haas UMC-500 five-axis machine, put it to the test machining a stainless steel aircraft galley cabinet latch.

Results on the Shop Floor

Robinette reported noticeable improvements in tool life and vibration control, and praised the vise for eliminating the need for dovetails in most applications, which simplifies setup and reduces time and cost for United Machine. Proprietary serrated jaws and clamping forces of 23kN (5,200 lbs.) for the DynoGrip 52 series and 34kN (7,650 lbs.) for the DynoGrip 96 series help prevent part movement during aggressive machining operations. “I’m routinely able to complete manufacturing of workpieces in one operation that previously required two or three,” he said.

While Robinette no longer needs dovetails, he will still use one when he wants to machine all sides of a workpiece in one operation. Mate jaws come standard with a 45° dovetail in addition to the serrated teeth.

DynoGrip’s quick-change jaw system is another key advantage, according to Robinette, because it enables him to switch from standard to soft jaws without tools, which saves additional time.

A Trusted Workholding Solution

Today, the DynoGrip vise is used to produce more than 300 stainless steel levers monthly at United Machine, which has added other Mate DynoGrip vises to its operation. Robinette said the consistency and reliability of the setup has reduced job complexity, which has helped with machinist retention.

Nothing breaks in Mate's DynoGrip vise, he noted. The jaws hold up, the jaw teeth remain intact and the part doesn’t move—all of which have resulted in an improvement in part quality, Robinette said.

“Before Mate,” said Robinette, “I wasn’t sure what would happen after starting the machine tool. I’d lose three or four parts per job. With Mate’s DynoGrip, I’m no longer concerned when I press the GO button.

“You can’t tear the Mate vises up,” he continued. “I run everything twice as fast and twice as hard as you probably should, but the Mate vises remain rock solid. They don’t back chatter. They don’t move. You can do things with Mate vises that you can’t do with anyone else. I haven’t found Mate’s limit yet.”

Supporting Automation

United Machine recently installed a Haas UMC-500 with a robot pallet loader and upgraded it from a 15-pallet to a 40-pallet system—with Mate vises on each. The automated cell now runs lights-out, overnight.

“These vises change how we program and cut parts,” Robinette said. “It’s hard to express how much of a difference they make.”

With decades of in-house machining experience, Mate developed its workholding systems to meet real-world shop demands and help manufacturers push their limits with confidence.

Contact Details

Related Glossary Terms

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.