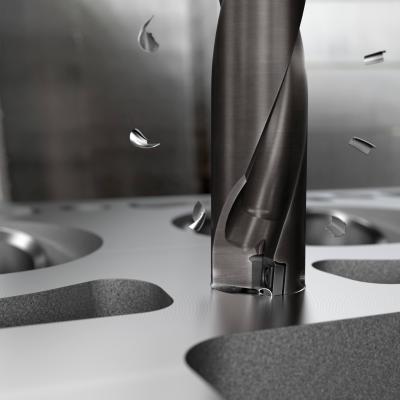

To overcome the challenges of chip formation and evacuation when drilling nonferrous metals, Sandvik Coromant has unveiled its CoroDrill 880 CVD diamond-coated insert grades, GCN124 and GCN134. The superhard properties of the diamond coating provide long tool life and combine with innovative chipbreaker and geometry designs to enhance performance when drilling materials such as aluminum.

“Making holes in aluminum can be a challenging task,” explains Patrik Pichler, global product manager, indexable drilling tools at Sandvik Coromant. “Ductility and softness cause the material to make constant and prolonged contact with the insert’s cutting edges. As a consequence, the aluminum adheres to the cutting edge and creates a built-up edge (BUE) that makes chip formation and evacuation difficult.”

GCN124 and GCN134 diamond-coated insert grades are designed to offer a low cost per hole in most ISO N materials thanks to long lasting insert tool life and/or greater productivity. The increased productivity could be gained from elevated cutting data as well as a result of less machine downtime thanks to fewer insert changes. Further advantages available to customers include easier handling in production thanks to the reliability and longer life of the inserts as well as enhanced surface finish inside the hole, which results from the ability to resist BUE and smearing effects. Reduced insert consumption will also help lower stock levels and environmental impact.

Among those set to benefit are automotive manufacturers drilling and boring aluminum components, such as cylinder blocks, cylinder heads, knuckles, housings, brake calipers, control arms, transmission cases, steering-column covers and yokes. Moreover, the diamond-coated inserts will also offer competitive gains to any company producing ISO N parts as well as those performing niche composite applications, such as drilling GFRP rotors/blades for the wind turbine industry.

To highlight the potential of the new grades, when drilling a 22 mm diameter blind-hole to a depth of 84.1 mm in a cylinder head made from 6061-T6 aluminum (90-100 HB), CoroDrill 880 mounted with the new N124 (peripheral) and N134 (central) inserts extended tool life from 700 to 3,024 pieces; a 332 percent increase. The new insert permitted increased cutting speed, allowing productivity to increase by 33 percent. In total, some 300 hours of production time were saved, while overall cost per hole was reduced by 23 percent.

Similar success was achieved when performing through-hole drilling (22.5 mm diameter) in 20 mm-thick automotive front control arms made from AISi1Mg-T6 aluminum (150 HB). Here, the new CoroDrill 880 diamond-coated inserts helped elevate tool life from 3,000 to 30,000 pieces. Productivity also improved by 10 percent as a result of less machine downtime for insert indexing, while cost per hole was reduced by 17 percent.

GCN124 and GCN134 complement the existing H13A, uncoated insert from Sandvik Coromant, which remains the recommended insert in applications involving shorter production runs and/or difficult interrupted cuts.

The standard CoroDrill 880 range features indexable insert drills from 12 to 84 mm (0.472–3.307 inches) in diameter, with drill lengths of 2, 3, 4, and 5 × D. With Sandvik Coromant’s Tailor Made offer, it is possible to order intermediate diameter and length combinations as well as different connection types and sizes such as HSK, Coromant Capto, or cylindrical shank. One of the Tailor Made options includes the ability to design customized step and chamfer drills for specific components.

Contact Details

Related Glossary Terms

- blind-hole

blind-hole

Hole or cavity cut in a solid shape that does not connect with other holes or exit through the workpiece.

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- built-up edge ( BUE)

built-up edge ( BUE)

1. Permanently damaging a metal by heating to cause either incipient melting or intergranular oxidation. 2. In grinding, getting the workpiece hot enough to cause discoloration or to change the microstructure by tempering or hardening.

- built-up edge ( BUE)2

built-up edge ( BUE)

1. Permanently damaging a metal by heating to cause either incipient melting or intergranular oxidation. 2. In grinding, getting the workpiece hot enough to cause discoloration or to change the microstructure by tempering or hardening.

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- indexable insert

indexable insert

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- through-hole

through-hole

Hole or cavity cut in a solid shape that connects with other holes or extends all the way through the workpiece.