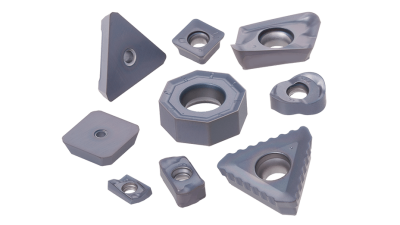

The AH3225 PVD-coated grade from Tungaloy Corporation is now available across a wider range of milling tools including high-feed cutters (MillQuadFeed), face milling cutters (DoOcto), shoulder milling cutters (TungTriShred), and ISO insert geometries such as SDKN42 and TEEN32.

To improve machining efficiency and extend tool life—particularly in ISO P steel applications, Tungaloy developed AH3225 with a proprietary “Triple Nano Coating” that the company says offers an excellent combination of wear resistance, fracture toughness, and oxidation resistance.

This technology ensures long tool life, minimizes dimensional variation, and delivers consistent machining quality even under demanding conditions.

The tooling grade provides resistance to crater and flank wear for extended tool life; reduced frequency of tool changes and stable machining across long production runs; and maintains surface quality and tight tolerances over time.

In addition, it enables faster cutting speeds and feed rates without compromising tool integrity. The tooling is ideal for high-feed and high-speed applications, reducing cycle times and overall machining costs

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flank wear

flank wear

Reduction in clearance on the tool’s flank caused by contact with the workpiece. Ultimately causes tool failure.

- fracture toughness

fracture toughness

Critical value (KIC) of stress intensity. A material property.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.