OSG USA Inc. released a range of new products to its tooling portfolio including end mills, drills and inserts.

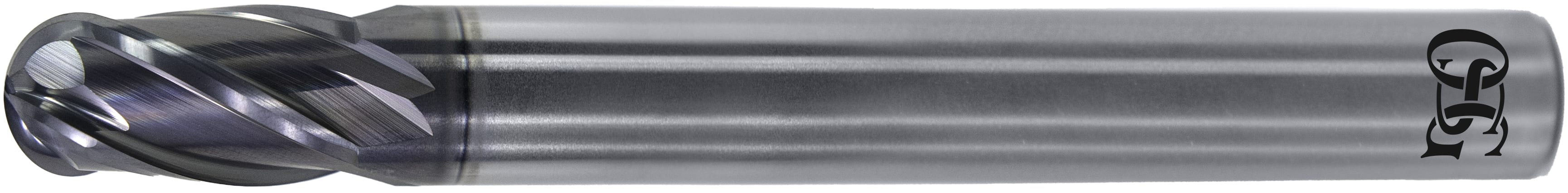

The end mill products include the A Brand AE-CPR2-H End Mill Series and the AE-CPR4-H, which is a series of advanced performance two- and four-fluted long neck corner radius end mills for hardened steels.

The following list numbers are associated with the expansion:

The A Brand AE-CPR2-H end mill offers the following features:

- 2-Flute Design - Low cutting resistance reduces tool deflection, ensuring a high-quality machined surface;

- Optimized 3D Negative Geometry - Balances sharpness and cutting-edge rigidity for superior performance;

- Flat Cutting Edge - Designed for bottom surface milling, achieving outstanding results with minimal tool wear while delivering higher precision and a smoother machined surface;

- Unmatched Corner Radius & Shank Precision - With a corner radius accuracy of ±0.002mm and an h4 shank tolerance for secure and stable tool holding.

The A Brand AE-CPR4-H End Mill Series features:

- 4-Flute Design - Achieves high efficiency milling with a 4-flute configuration across all sizes in List #8592;

- New Spiral Gash - For Improved chip evacuation and suppression of chatter

- Unequal Index - Suppresses chatter to enable high speed, deep reach milling

- Unmatched Corner Radius & Shank Precision - With a corner radius accuracy of ±0.002mm and an h4 shank tolerance for secure and stable tool holding

The company also released new versions of it Exocarb end mill series, including the Exocarb WXL-EBM. The Exocarb WXL-EBM is a series of premium performance

carbide end mills with OSG’s proprietary WXL coating.

The following list of numbers are associated with the expansion:

The Exocarb WXL-EBM end mill offers the following features:

- Ultra-Fine Micro-Grain Carbide - The hardest, most wear-resistant carbide possible for wear resistance, the company says;

- High Precision Geometry - High accuracy all but eliminates the need for benching and rework for mold makers;

- High Strength Core Diameter - Tools utilize thicker core diameters for ultimate strength and rigidity;

- WXL Coating - Higher coating oxidation temp & hardness dramatically improve wear resistance.

The Exocarb SEP-EL is a series of DLC coated carbide end mills for super engineering plastics.

The following list numbers are associated with the expansion:

The Exocarb SEP-EL end mill offers the following features:

- DLC-IGUSS Coated - Combines microscopic tool sharpness & tool wear resistance while achieving a good surface finish in a range of plastics from engineering plastics to super engineering plastics;

- 3 Flute with Low Helix, Specialized for Resins - Cutting tool design allows for low cutting forces, reduced heat generation, and burr free machining;

- Strict Dimensional Control with Tool diameter Tolerances of 0.001" or Better - High accuracy tooling designed for the demanding needs of the semiconductor industry;

- Cutting Edge Ground to a Point - Resulting in a sharp cutting edge for free machining in resins

Drill series

OSG USA also announced the expansion of the A Brand ADO-40D and 50D Drill Series. The series now includes additional sizes in its offering. The A Brand ADO is a series of high-performance coolant-fed carbide drills for ferrous and non-ferrous materials.

The following list numbers are associated with the expansion:

The A Brand ADO-40D and 50D drill offers the following features:

- OSG's EgiAs Nano Coating Technology - Higher coating oxidation temp & hardness improve wear resistance;

- Wavy form cutting edge design - Sharper cutting action reduces thrust forces and produces smaller chips for easy hole processing;

- Internal Coolant Holes - Coolant delivery at the cutting edge reduces heat and improves chip evacuation, thereby increasing tool life and enabling faster drilling speeds.

New inserts

Finally, OSG USA released the OSG Phoenix PSF and PSFL insert. The insert is a 90° indexable shoulder cutter for face milling.

The following list numbers are associated with the expansion:

The Phoenix PSF/PSFL MCD Insert offers the following features:

- Square Insert with 4 Cutting Edges - High performance with long insert life and low cost per edge;

- Compact Insert Size for Lighter Depths of Cut - Superior performance in face milling applications;

- Sharp 3-Dimensional Chip Breaker - Reduced cutting forces;

- End Mill and Face Mill Styles, Inch and Metric - Complete offering

Contact Details

Related Glossary Terms

- burr

burr

Stringy portions of material formed on workpiece edges during machining. Often sharp. Can be removed with hand files, abrasive wheels or belts, wire wheels, abrasive-fiber brushes, waterjet equipment or other methods.

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- ultimate strength

ultimate strength

Maximum conventional stress (tensile, compressive or shear) that a material can withstand.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.