Contact Details

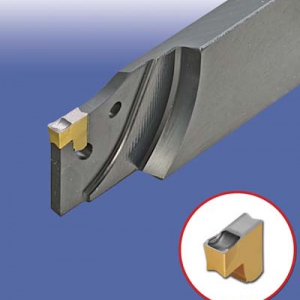

Deep hole drilling is very popular in the automotive, die and mold and aerospace industries. ISCAR took the gundrill technology one step further when developing the new CHAMGUN for deep hole drilling; this is a gundrill that enables the replacement of drilling heads while the driver is still connected to the machine. The "No Setup Time" concept enables quick head changes without the need to remove the drill from the spindle while indexing. The CHAMGUN is the ultimate economical solution for deep drilling. A polyamide plastic key is used for clamping and removing the CHAMGUN head.

A single CHAMGUN body can carry many different types of drill head profiles, designed for use on various materials. Each drill body can carry standard drilling heads within a range of 0.2 to 0.3mm. the CHAMGUN drill range is 9.8 to 16.19mm. drilling heads are available in half and whole sizes as standard items. Each drill pocket can carry a variety of drilling head diameters and head geometries.

The drill features an innovative unique pocket which can sustain at least 15 head replacements. The connection between the pocket and tube is by a new welding process for high torque resistance. Each drill pocket can carry a variety of drilling head diameters and head geometries and chipbreakers designed for use on various materials. ISCAR's GDI inserts can be reground a minimum of 10 times. However, head length should not be shortened to less than L-D. The end result is excellent straightness and concentricity inside the hole with high hole precision center alignment. In addition, surface roughness is easily obtained within the range of 0.4-1.6 Ra.

Additional features:

Carbide grades — coated and uncoated

Profiles — standard pad profiles

Drilling precision of IT7 to IT9 tolerance can be achieved

Re-boring is often unnecessary It is possible to regrind and recoat the drilling head up to 10 times, still obtaining good repeatability.

Related Glossary Terms

- gundrill

gundrill

Self-guided drill for producing deep holes with good accuracy and fine surface finish. Has coolant passages that deliver coolant to the tool/workpiece interface at high pressure.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.