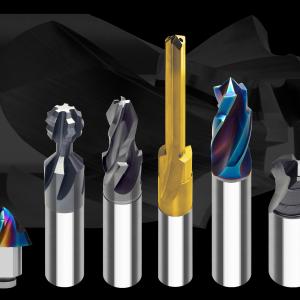

Milling

Oakland Community College Closes the Skills Gap with Hurco

Hurco is proud to partner with educational institutions to train the next generation of CNC machinists. Join us as we tour Oakland Community College’s advanced facility to see why top-notch manufacturing curriculums choose Hurco.

Please visit Hurco.com to learn more about our company.