Westec 2023 Booth Visit with ARCH Cutting Tools

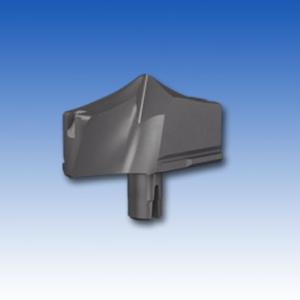

ARCH Cutting Tools highlighted its RECON360 service program at its booth during Westec 2023 in Long Beach, California. Just over a year old, RECON360 offers to:

- restore solid round tools and indexable cutting tool bodies to OEM or new condition,

- braze new carbide, CBN, PCD or ceramic edges on inserts and round tools,

- reapply coating to tools,

- regrind worn areas on inserts and solid round cutting tools,

- resize inserts or solid round tools.