CTE Booth Visit with Allied Machine & Engineering @ Eastec

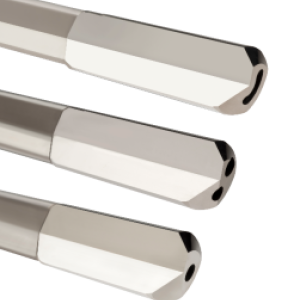

Allied Machine & Engineering's Kevin Vanderbeck, field sales engineer for the New England territory, discussed the company's T-A Pro drilling line for stainless steel geometries along with a variety of other products on display during Eastec 2023.