Thread Milling Machining Parameters

Thread Milling Machining Parameters

While delving into thread milling for this column, Brandt Taylor met and learned something new from an EMUGE-FRANKEN expert on high-volume production.

Over my career I've made thousands of different parts for a manufacturer of industrial and military machines. The volumes were usually in the single digits.

While I consider myself an expert in small-lot precision machining, high-volume part production is another matter. While working on my thread milling articles for this column, I met an EMUGE-FRANKEN USA engineer who is an expert on high-volume production.

Before writing last month's "Intro to Thread Milling," I did not think a thread mill existed that cut perfect threads. Years ago, I used thread mills to make parts. The threads had concave flanks. That is OK for many applications, but it can cause trouble if the application has a high load factor.

I have learned that EMUGE makes tools that cut perfect V threads. If you missed last month's column, and you are interested in thread milling, you should read it. EMUGE's thread mills have a flat at the point of the V. Each mill is made for a small range of threads. This means there is a little more axial backlash with a loose bolt in the hole, but when the bolt is tightened the assembly is precise. EMUGE makes plug gauges for testing the cut threads.

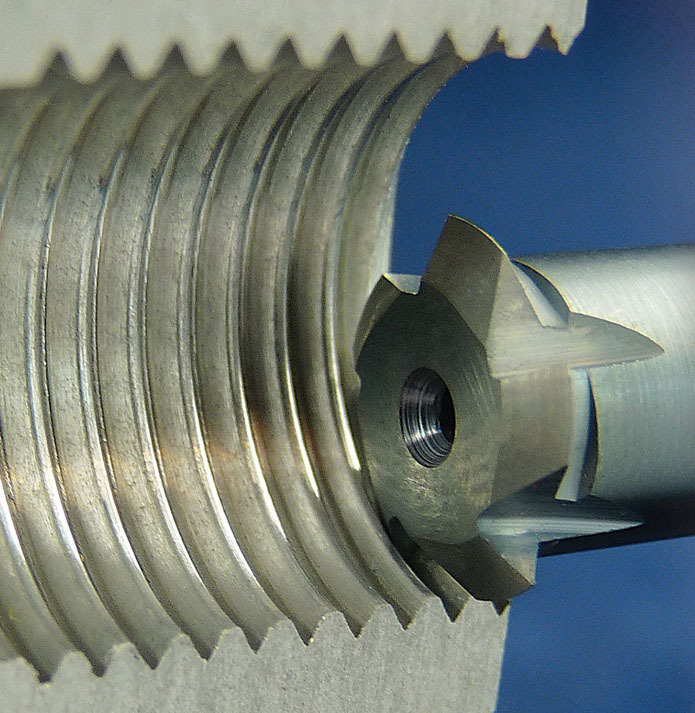

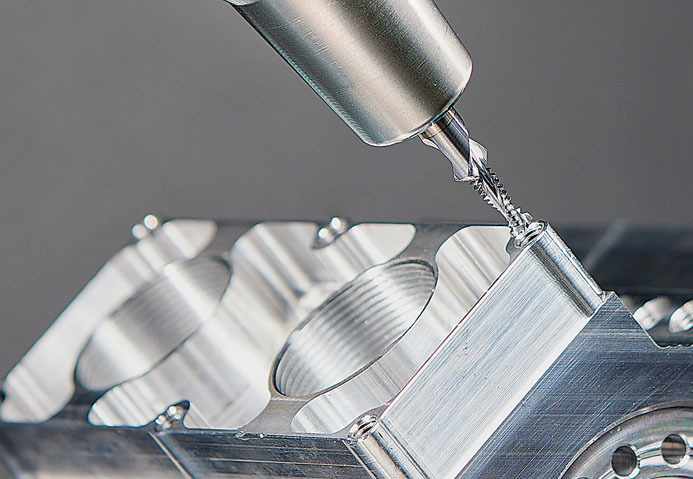

Figure 1 shows a single-plane tool in a cutaway thread. Figure 2 shows a multi-plane tool called Thriller. The company also makes tools that will drill and thread a hole in a single pass. I will be writing about those tools in a future article.

Deeper dive

For this report, I dove deeper into EMUGE's thread milling products. They have features that are unique. EMUGE uses sophisticated grinding operations to reduce the clearance angle on the cutting edges. This produces better edge strength, which makes for longer tool life. Also, the company offers resharpening and recoating services for thread mills in Germany and offer these same services for their drills, taps and endmills in the U.S. And, if a customer needs a longer length of cut (LOC) than can be made with a standard tool, EMUGE can make the neck of the tool longer for that longer LOC. This is done here in the U.S.

Climb or conventional milling

Climb milling or conventional milling both have advantages and disadvantages. With climb milling there is a greater tendency for the tool to chatter so feeds and speeds often need to be less than those used in conventional milling. On the other hand, with conventional milling, the cutting edges rub when entering the cut so tool life is less.

I prefer climb milling as I have found I get better part quality and consistency, and, because of my low-volume situation, the longer cycle time is not an issue. EMUGE has data and recommendations for whatever volume you need to tackle.

Speeds and feeds

Now to feeds and speeds. Like other carbide tools, cutting speeds are 200 to 600 feet per minute depending on the workpiece material and machining conditions. My bible for speeds and feeds is the Machinery's Handbook, which provides such data through a host of tables. EMUGE also has tables and knowledgeable people to assist you.

Remember, the temperature of the cutting edge influences tool life greatly. Keep it cool. Chip load on the cutting edge with cutting speed determines feed rate. A good place to start is 0.0005" to 0.0012" per tooth. Cutting a thread with two passes is a safe bet. Cut 70% of the depth of cut with the first pass and 100% with the finish pass.

Where to start?

When doing thread milling, I like to start the cut at the deepest tool position in the hole and cut while retracting the tool. With a right-handed thread this will produce climb milling. This way, if the tool breaks or something else goes wrong, it is less likely to cause a damaged workpiece.

Here is a programing example for using an EMUGE Thriller to cut a 1/2-20 thread, 0.60" deep. This program uses polar coordinates to cut the thread in two revolutions of a helical tool path. The first revolution is at 70% of the depth of cut, and the second revolution at 100% finishes the thread. The center of the hole is at X4.Y3.Z0.

N1T20M06

N10S1200M03

N20G90G15G0X4.Y3.Z.1

N30G1Z-.6F100

N40G16G1R0.056A90I4.J3.F40

=N50/500

N50G91A-.72Z.0001F40

N60G15G1G90X4.Y3.F100

N70Z-.6

N80G16G1R.063A90I4.J3.F40

=N90/500

N90GG91G1A-.72Z.0001F40

N100G15G1G90X4.Y3.F100

N110G0Z.1

N120M02

It seems to be easier for me to find bugs in helical programs using polar coordinates. It's nice for doing bolt circles too.

I have always found it more fun to make money than to make scrap.