Lauding Light Cutting

Lauding Light Cutting

If a milling strategy comes along that promises critical advantages like higher productivity & longer tool life, it should be no surprise shops flock to it

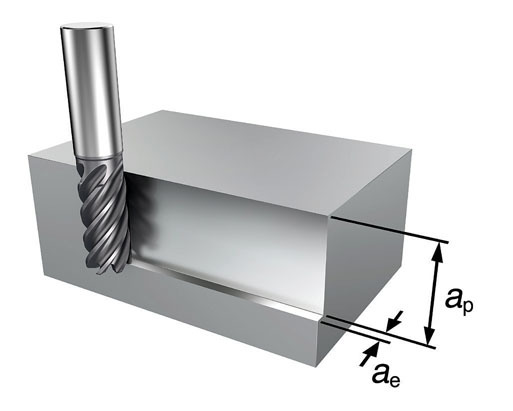

If a milling strategy comes along that promises critical advantages like higher productivity and longer tool life, it should be no surprise that shops would flock to it. And such has been the case with high-efficiency milling (HEM). Characterized by smaller radial depths of cut and larger axial depths of cut, HEM's relatively light touch is also power-saving and machine-friendly. What's more, HEM has become even more effective in recent years thanks to developments in areas such as tooling and software.

On the shop floor, one of the main aspects of HEM machinists appreciate is that "they're not changing tools all the time," noted Keith Carlile, national milling product manager at Iscar USA in Arlington, Texas.

HEM employs the full length of the tool, spreading heat and wear along the entire cutting edge. As a result, "it wouldn't be out of the ordinary to see double, triple, even four times the tool life by implementing a high-efficiency strategy," said Nathan Peynado, metalworking applications specialist at MSC Industrial Supply Co., which is dually headquartered in Melville, New York, and Davidson, North Carolina.

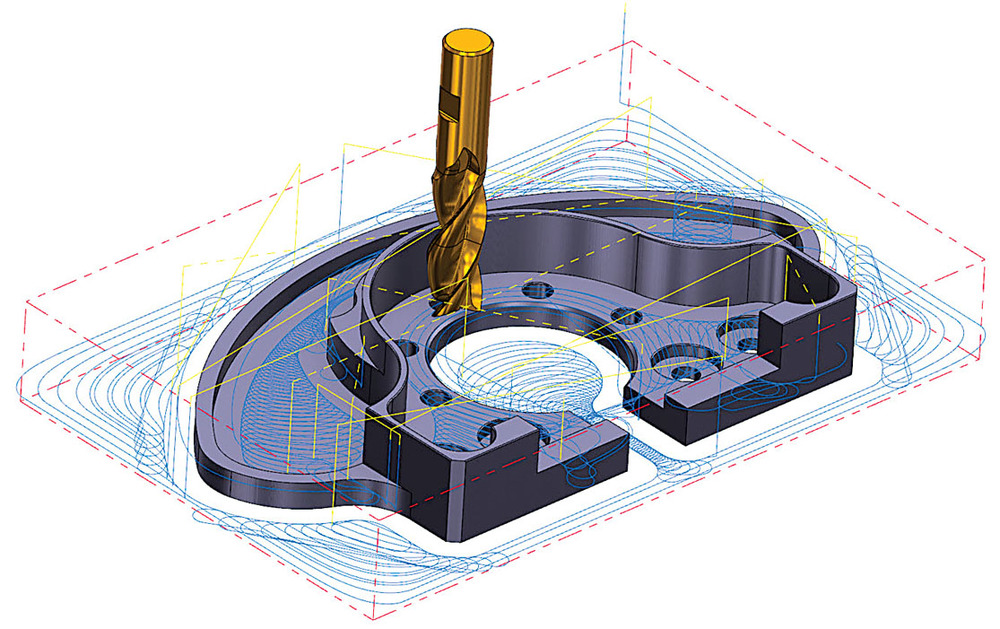

HEM tools also benefit from the special CAM-generated toolpaths — trochoidal, adaptive clearing and constant engagement, for example — that are employed when machining complex parts. These produce lower peak cutting forces than traditional roughing, which can cause high load spikes while cutting corners and curved features, noted Mike Gomez, principal R&D engineer at MSC Industrial Supply.

High metal removal rates

In addition, HEM offers high metal removal rates compared to conventional milling processes, in which wear is concentrated on a smaller tool area. Employing HEM, "you're removing massive amounts of material, and you're not destroying tools," said Michael Stone, owner of Dynamic CNC USA LLC in Fort Lauderdale, Florida. Stone added that the technique allows the same endmills to be used for months. Providing contract machine programming and setup, Stone often visits shops with MSC's Peynado. Together, the two can get a HEM process up and running and also optimize an existing process.

Thanks to high MRR, increases in productivity can be dramatic. When shops adopt HEM, "sometimes we see more than 50% increases in output," said John Giraldo, engineering projects manager for the Americas at Sweden-headquartered Sandvik Coromant.

A lighter load

While giving a big boost to productivity, HEM can also reduce power consumption. With HEM doing lighter radial passes, high horsepower isn't required, Carlile explained, noting that HEM is unlike "the old-fashioned way — get a big tool and take as big a cut as you possibly can — [that] requires a lot of torque and horsepower."

A related bonus, he added, is that the technique is easy on machine tools, especially when more challenging materials are being cut. Benefits in this category include less stress on bearings and lower spindle loads.

As a result, Peynado said, HEM is accessible to shops that don't have machines that are big and rigid enough for conventional milling of harder materials like exotic alloys and some stainless steels. "High-efficiency milling places so light a load on a machine that some of the more inferior machines are now capable" of cutting these materials, he noted.

In addition, Stone pointed out that HEM workholding doesn't have to be as "crazy rigid" as would be rerequired to take big cuts in challenging materials.

Best HEM practices

To make a good thing even better, shops implementing HEM can benefit greatly by following the guidance of experts on the subject. For example, Gomez recommended that shops consult the tool recommendation applications or tool guides offered by tooling manufacturers. These suggest HEM-style strategies such as adaptive clearing and trochoidal milling alongside other process recommendations (feeds and speeds, depths of cut, etc.) for cutting different materials.

Also helpful are tool-related programs like that offered by MSC's metalworking team, in which tools are tested to evaluate different cutting approaches before customers pay for the tools. After considering a particular HEM challenge, for example, Peynado will choose an MSC tool that he thinks will provide optimal results. Using this tool and the customer's machine, he and Dynamic CNC's Stone work together to test the tool and a machining strategy for the application. According to Peynado, the result could be an 80% reduction in the time required for a particular machining job.

In the area of process improvement, Giraldo pointed out that HEM generates a lot of chips that must be cleared out of the cutting zone to prevent recutting that could cause a tool to wear out prematurely. For effective chip evacuation and help with heat management, he recommends the use of high-pressure air blast or high-pressure coolant, depending on the material being cut.

Other keys to maximizing the success of a HEM process involve the machine tool used for the job. According to Gomez, an important decision in this area is whether to choose a horizontal or vertical machine tool. With a horizontal machine, a shop is working with gravity during machining, so chips are probably falling away from the part. Using a vertical machining center, however, chips are potentially falling back into the cutting zone, so there is a risk of recutting. "That's not to say you can't use a vertical machining center," he said. "But when it comes to deploying this strategy successfully, things like that can play a big role."

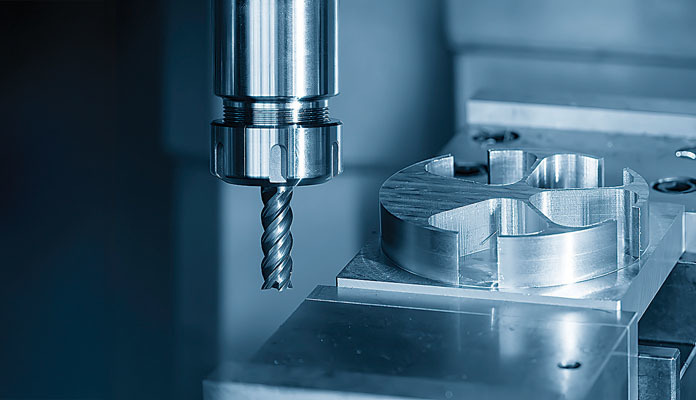

When a machine is tasked with a high-efficiency milling job, one thing to be aware of is that it might not be able to run as fast or move as quickly as you want it to, according to Carlile. If the computer program for a machining process says the operation should take 10 minutes, but the machine actually takes 20 minutes to complete it, the operation isn't going to run correctly or well, he explained. So, if the computer-generated and actual cycle times don't match, he urged shops to make changes in the programming so the operation lines up with what the machine is capable of doing.

Another thing to keep in mind is that HEM toolpaths like adaptive or trochoidal include very rapid changes in direction. "With some workhorse machine tools, when you try to run some of these complex paths, you can see the machine tool struggle to get up to speed," Gomez said. If it can't process code extremely quickly and doesn't have sufficient "look-ahead" capabilities, he noted, the result will be jerky motion that can cause gouging, chatter and inconsistent surface finish.

This lines up with what Peynado once witnessed when he put a HEM program into an older machine. "It was pausing every step of the way, and the program wasn't able to run efficiently," he reported. "So, if you're not running a newer machine, high-efficiency milling may not be an option for you."

Even if a machine is up to the job of running a HEM program, that doesn't guarantee a problem-free process. For one thing, "the machine is moving so fast, you can't stop in time if something's going wrong," Stone noted. "So [things] are already broken before you know what happened."

To catch process flaws before they cause costly mishaps, Peynado recommended simulating untried HEM routines using one of a number of different software products developed for that purpose.

When it comes to toolpath styles, shops that decide to employ HEM have many options, ranging from basic to advanced and produced using CAM software from many companies. Whatever CAM product a shop opts for, "make sure you're trained up on your software," advised David Miller, manager of product marketing engineering at Mastercam in Tolland, Connecticut. Mastercam's Dynamic Motion toolpaths for HEM are part of the company's standard course curriculum, which is available online and in classroom settings at all of Mastercam's regional offices. To get even better acquainted with the Mastercam program's style of motion and settings, Miller also recommended that users work with their local Mastercam representative and a tooling provider to do a test cut prior to the start of real machining.

Notable Developments

In addition to the long-recognized advantages of HEM, experts highlighted recent developments that are good for anyone employing the technique. Today, for example, Gomez reported that many high-end machine tools are equipped with advanced controllers that make use of sensors. With sensors on machine tools and smart toolholders, "now you're able to measure forces or loads closer to your cutting tool so you can make adaptive changes in real time," he noted. With this kind of force and vibration data, shops can refine HEM parameters to improve tool life and efficiency.

HEM has also become a more common choice for tackling the most challenging materials. "In the past, people thought of high-efficiency milling as something just for softer materials like aluminum and brass," Peynado said. "But we're starting to see it [used with] stainless steels, Inconels and exotic materials with great success."

Moreover, Peynado has noticed that toolmakers are reacting to the growing popularity of HEM. "The high-efficiency milling strategy has been around in the industry for quite some time," he said, "but now we're starting to see a lot of tooling manufacturers catching up and creating tooling specifically for this application."

According to Giraldo, toolmakers have changed overall endmill geometry to better suit HEM applications. As a result, he said, machinists skimming through Sandvik Coromant's tool catalog will see the designation "high-feed side milling," which indicates that a tool would normally be used for high-efficiency milling.

Distinguishing characteristics of HEM tools include unique edge prep and eccentric grinds around the relief face of the flutes to help with heat management, Gomez noted. In addition, HEM tools feature a variable pitch, variable helix cutting flute design. "Traditionally, endmills have had evenly spaced flutes. So, when they're running at higher feed rates like you typically do with HEM, it's easy to hit a resonant frequency that leads to chatter or unstable cutting," Gomez said. Now, however, "you see a lot of newer tools with slightly offset flute spacing — that is, variable pitch." As for variable helix, he explained that varying helical angles helps break up cutting forces into different frequencies, further reducing the risk of chatter.

Another key to the success of HEM tools is the grade optimization that toolmakers have undertaken. While an uncoated, off-the-shelf endmill might take 15 to 20 minutes to cut a feature in hard-to-machine materials like nickel-based alloys, the cycle time might be only five to seven minutes using an endmill coated with a grade optimized for those materials, Giraldo noted.

In recent years, HEM has also benefited from increased collaboration between CAM developers and tooling manufacturers. For example, Miller reported that Mastercam is constantly working with the R&D departments of many top tooling manufacturers. One result is the development of new and enhanced toolpaths aimed at getting the most out of new tool geometries.

In addition to tooling and software developments, Gomez pointed out that HEM has gotten a boost from the emergence of anti-vibration toolholders. "HEM is pretty vibration-friendly," he said, "but being able to dissipate any vibration allows you to (run) your tool and machine tool a lot faster and take heavier cuts with HEM."

Taken together, the inherent benefits of HEM and the advances that have improved the process seem to make a compelling case in its favor. Based on the results Stone has seen in his experiences with MSC's Peynado, he's surprised more machine shops aren't HEM converts. "It's made a huge difference in the shops that Nate (Peynado) and I work in," he said. "Usually, the owners are blown away by how much we can decrease cycle times and also produce beautiful parts."