Zero Is The Point

Zero Is The Point

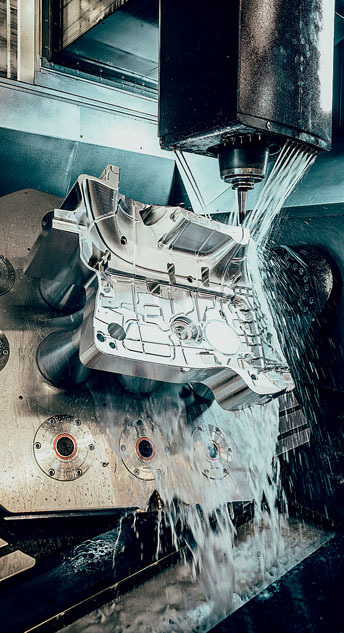

Reducing setup time between jobs and enabling a machine tool to spend more time producing chips boosts the bottom line.

Reducing setup time between jobs and enabling a machine tool to spend more time producing chips boosts the bottom line. A workholding technology that enables this scenario is a zero-point clamping system.

"It's pretty much no setup time," said Thomas Saur, president of HWR Workholding USA Inc. The Fortville, Indiana, company offers the SolidPoint and SolidBolt mechanical zero-point technologies.

He added that if an end user uses a robot to take a vise in and out of the machine, changeover occurs entirely externally, so setup time is basically eliminated. "It's just the time to take a vise out and put another vise in."

The manually actuated SolidPoint offers the possibility of combination plates that include both 96 mm and 52 mm grids in one plate. With two locking slides and a threaded spindle with opposite rotation, the company reports that the mechanism consists of only three components and therefore has minimal friction losses. The locking force within the mechanism is applied at a 45° angle, which increases pull-in force and provides repeatable, safe clamping results. The wedge system has a repeatability of 5 μm (0.0002"), Saur noted.

The design of SolidBolt is based on an optimization of the SolidPoint principle, according to HWR. By reversing the interaction of zero-point mounting and studs, SolidBolt can be used to equip a large machine table for a low cost. This means that machine tables or base platesare equipped with bolts and not with zero-point mechanics, and zero-point technology is only used punctually at the required points.

SolidBolt is basically a reserve system, according to Saur. A large machine table could require four or six SolidPoint plates, which are expensive because they contain internal mechanics. On the other hand, SolidBolt base plates do not contain internal mechanics and fit practically all machines. Pull studs can be placed wherever they are needed on a machine table. Zero-point mechanics are housed within the vises, allowing them to only be applied where needed. "Then, with a very big part, you just put devices in different corners of the table, and you can clamp parts up to 800 mm wide and the length of your table."

Because of the minimal setup time, Saur explained that a 40-part run, for example, can be interrupted to do an emergency five-part run by bringing vises into the magazine, calling up the part number and then quickly continuing the larger part run. "You have a higher investment in workholding at the beginning, but then, since you don't have setup time, it pays back fairly quickly."

He estimated the return on investment is six months. "If somebody does a lot of setups and uses the zero-point system, it pays back in no time because a regular setup takes you an hour, and you can go down to seconds."

Quick-Change Efficiency

Driven by the lack of skilled labor, Tom Dang noted how automation continues to be the buzzword for part manufacturers. He is vice president of Mundelein, Illinois-based Lyndex-Nikken Inc., which offers the Zero Point clamping system from Zero Clamp GmbH in Germany.

And the predecessor to automation, which is essentially robotics lending a hand, is workholding, Dang said. "If you don't have the right type of workholding in place, you shouldn't be thinking about automation. That's too wide of a gap to bridge. Workholding is that bridge between where you are today and where you want to go tomorrow, which is automation."

Conventionally, putting a work-piece into a fixturing device requires a user to perform many functions manually, such as indicating and setup, Dang said. "You have a datum point already established on the Zero Point system and that's what they mean by the term zero point — it is the reference point. You don't have to dial that in anymore."

With the Zero Point system being the baseline that provides the reference point, he added that what goes on top of the Zero Point system is even more critical because not all parts are easily clamped on a vise or some other device.

Zero Point is predominantly used for milling, Dang said, and the system typically requires two Zero Point pots for alignment purposes because lineage cannot be built with one circular pot. In conventional workholding, the entire vise is bolted down and cannot be moved, whereas with Zero Point the vise can sit on a plate that has a clamping stud. "I can put that whole vise on to that Zero Point system. The whole vise can come off and the whole vise can come back in within seconds, without indicating the clamping stud or the clamping part."

Dang added that the option is available to just move a billet while the vise stays inside the machine by changing a robot's end-of-arm tool to grab the billet rather than the entire vise. "Zero point is the base unit with variations of top tooling. It makes it flexible and efficient for various machining applications including unmanned machine tending."

Thermal Symmetry

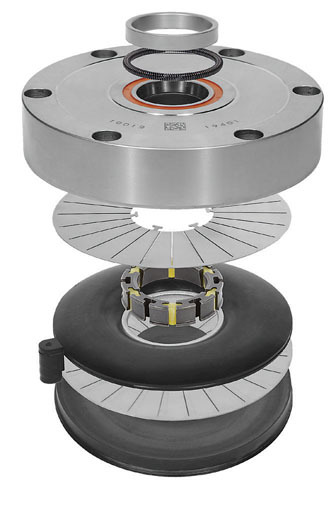

Hoffmann Quality Tools USA Inc. is another provider of zero-point clamping systems with its Garant ZeroClamp. Paul Lanham, application engineer for the Knoxville, Tennessee, tooling manufacturer, emphasized that due to the central zero point, the system provides thermal symmetry at all times and is therefore a "true, absolute zero point. It has thermal symmetry, so it can pull individually from each clamping pot."

According to the company, conventional clamping technologies that use floating studs to compensate for thermal expansion produce inaccurate results if workpieces are rotated around the central axis. Garant ZeroClamp, however, does not have floating studs nor sword studs, and compensation for thermal expansion is always symmetrical about the central axis.

"It can pull in all four directions to keep your part centered. It repeats within 2 μm," Lanham added. "When you are pulling in one direction, your part wants to grow or move and then you have tolerance issues."

When it comes to reducing setup time, Lanham said for midsize parts, customers generally reduce changeover time by 90%, and one customer with small posts on the bottom of 127 mm × 127 mm (5" × 5") parts reduced the time by 98%. "It's one touch off and go. He can have a program loaded in under a minute and he's rolling."

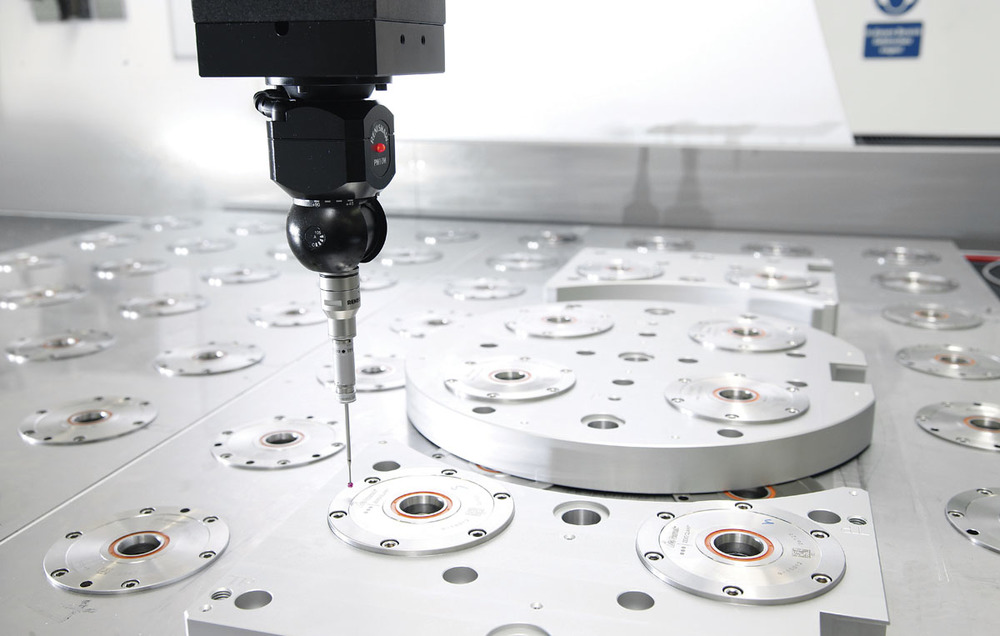

The zero-point system is also suitable for large applications. For example, he noted that one German customer has 60 clamping pots on the table of a large machining center. "He has 60 different pickup locations where he can load programs from. He doesn't need or want one monstrous plate that he drops on there. He can be up and running in seconds."

Another advantage of the system is it only requires 5.5 bar (80 psi) of compressed air to release the clamping studs, and locking is by spring pressure, Lanham said. "You open up the doors, you plug your air line in and, as soon as you take the air line off, it's clamped. You don't have to have all this custom piping. We do offer it if it's needed for more automation."

In addition, the low-maintenance, sealed system functions without hydraulic oil.

He added that the 120 mm-dia. (4.7") clamping pot provides 25 kN (5,620 lbs.) of clamping force and the 138 mm one offers 40 kN (8,992 lbs.) of clamping force. "It's not going to go anywhere."

Another zero-point highlight is that the system can be rebuilt with a kit, Lanham said. "We can send it back to Europe, but we would really like to go through it with them [customers] and have them do their own thing. It can be completely taken apart and put together with the same parts, and you have a brand new system. The whole locking unit is made so that it can be broken, and you can repair it."

An end user can even build a zero-point clamping system in-house to overcome logistics and global supply chain problems, as well as time and cost issues, Lanham noted. Hoffmann supplies the schematics and prints, and the customer purchases the materials. "They just make their own zero-clamp plate and install all the pots and air lines and quick connectors. We do it inhouse with their machines and their people."

Inspection Ease

HWR's Saur concurred that parts can be purchased to replace any component on the zero-point clamping system when repairing it. Training operators is straightforward but it's critical they understand the need to stay within the recommended torque range when tightening components. "Don't over torque your plate or your vises because if you do, something will break. If that happens, we can replace the spindles easily, but it's better to avoid the unexpected."

In addition to using a zero-point clamping system for machining parts, the system is also suitable for quickly doing first article inspections, Saur said. "In our case, you would have a zero-point plate on your CMM. You take the whole vise out, you put it in the CMM, you bring it back and you can re-machine it."

He added that there are multiple ways a zero-point clamping system can save time. "If shops understand what zero point can do, they will buy zero-point systems. Maybe not from us, but they will buy it if they understand the advantages of it."

Lyndex-Nikken's Dang added that using Zero Point for inspection purposes enhances repeatability because a part can be inspected with the datum point already in place. "Anytime you unclamp a workpiece from its clamping element, you're exposing it to material changes, expansion; things move around and then you try to put it back into an inspection machine and you have to recreate that datum point. You don't need to do that with a Zero Point system as it can be used in machines for milling, turning, spark erosion and quality assurance. As the datum is already established, you simply remove the clamping unit with the part in it from one machine and put it in the inspection machine."

Regardless of the application, zero-point clamping technologies are enhancing efficiency by reducing setup times and helping to overcome the skills gap by enabling more automation, Lanham said. "People are moving forward, and the way the world is changing — less and less people — more and more automation is on the shop floor."