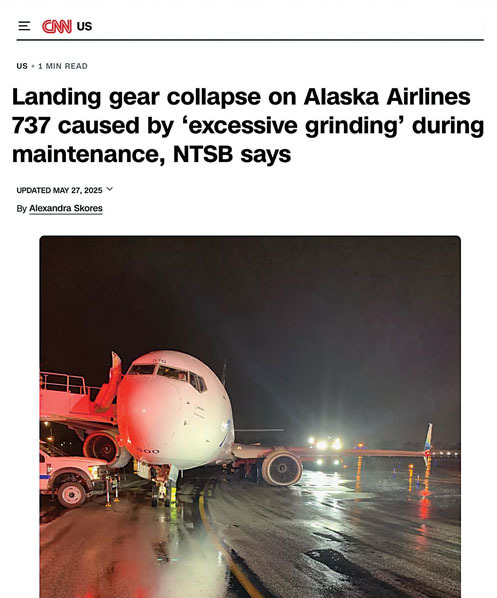

Dear Doc: What’s your take on the recent finding that bad grinding caused the landing gear to fail in the Alaska Air Boeing 737?

The Doc replies: It’s an interesting case. My comments are based on the Aviation Investigation Final Report about this accident as published and made public by the National Transportation Safety Board (NTSB). I downloaded the report from the NTSB’s Aviation Investigation Search page — www.ntsb.gov/Pages/AviationQueryv2.aspx — by using the NTSB Status search tool on that page. I entered the number assigned to the accident by the NTSB — DCA23FA417 — into the “NTSB #” field, selected “Completed” from the “Report Status” drop-down menu and then clicked the “Submit Query” button.

The report is only 13 pages and doesn’t include information I consider necessary to develop a complete understanding of the situation: surface roughness (on the base material and the chrome layer), a residual- stress-versus-depth profile, a typical S-N curve for this material, design criteria, microscope photos showing the depth of the overtempered layer, etc. But it does contain enough information for me to formulate a basic opinion.

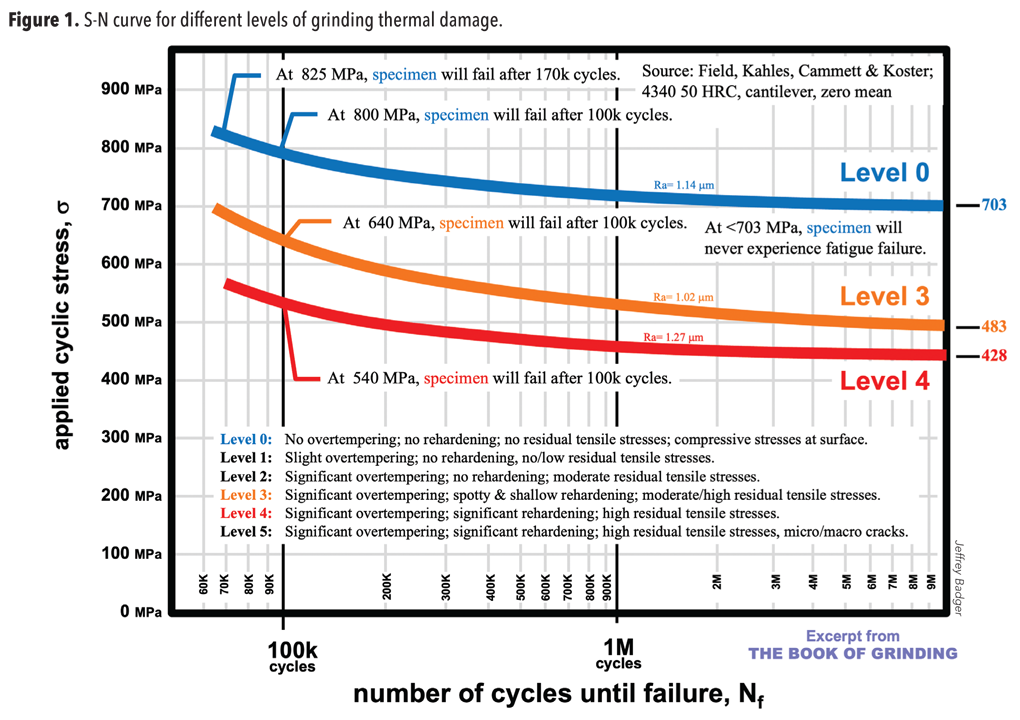

First, let’s look at some fundamentals. A given material can withstand a certain level of stress before it breaks. But that level is a moving target of sorts. If that material is placed in a repeated stress-no-stress situation — for hundreds, thousands or even millions of cycles — the level of stress it can endure will be lower. That’s called “fatigue failure.” In more specific terms: Let’s say I pulled on a rod once with 60 pounds of force and it broke. Then I pulled on a rod with 50 pounds and it didn’t break. Then I repeatedly pulled on a rod off-and- on with 50 pounds and it broke after 3,000 pulls. Next, I repeatedly pulled on a rod with 40 pounds and it broke after 30,000 pulls. Finally, I repeatedly pulled on a rod with 30 pounds for a billion pulls, and it never broke. The last one is the “endurance limit.”

Figure 1. S-N curve for different levels of grinding thermal damage. Jeffrey Badger

Figure 1. S-N curve for different levels of grinding thermal damage. Jeffrey Badger

A CNN article describing the National Transportation Safety Board’s findings about the landing-gear failure. Screenshot from CNN website

A CNN article describing the National Transportation Safety Board’s findings about the landing-gear failure. Screenshot from CNN website

What causes a reduction in fatigue life? Lots of things: microcracks, inclusions (i.e., dirt), voids, large carbides, incorrect heat treatment, sharp corners and corrosion, among others.

What about the causes related to grinding?

- A rougher surface finish (with the grinding scratches in the same direction as the stress) can decrease fatigue life somewhat.

- A rougher surface finish (with the grinding scratches perpendicular to the direction of the stress) can decrease fatigue life a lot.

- Overtempering (due to higher grinding temperatures) reduces fatigue life.

- Residual tensile stresses (due to even higher grinding temperatures) reduce fatigue life even more.

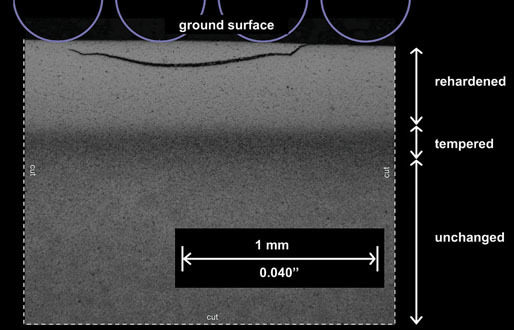

- Rehardening burn (due to even higher grinding temperatures) reduces fatigue life even more. (And, if you have rehardening, you almost certainly also have some overtempering just beneath the rehardening.)

Figure 2. A ground workpiece with both rehardening and overtempering. Most workpieces with thermal damage do not have cracks. However, cracks might form later, precipitated and/or accelerated by the thermal damage. Jeffrey Badger

Figure 2. A ground workpiece with both rehardening and overtempering. Most workpieces with thermal damage do not have cracks. However, cracks might form later, precipitated and/or accelerated by the thermal damage. Jeffrey Badger

The graphic in Figure 1 shows a basic S-N curve (stress versus number of cycles to failure) for 4340 steel at 50 HRC. (The Alaska Air Boeing 737 landing gear was made of some other grade, so this is just an example.) The graphic shows:

- Level 0 — defined as gentle grinding (no grinding thermal damage) — gave a certain fatigue-life curve.

- Level 3 — defined as moderate grinding thermal damage (which induced overtempering and spotty rehardening) — reduced fatigue life.

- Level 4 — defined as severe grinding thermal damage (which induced overtempering and uniform rehardening) — reduced fatigue life even more.

Endurance limits were reduced from 703 MPa (Level 0) to 483 MPa (Level 3) to 428 MPa (Level 4).

For a different material, the same researchers found that in the lower-cycle-fatigue region, for a given stress, moving from Level 0 to Level 4 reduced fatigue life from 10,000 cycles to 3,000 cycles (70%). At a lower stress, it reduced it from 70,000 cycles to 30,000 cycles (57%).

These are different materials and different conditions. But they give us a ballpark idea of how different levels of grinding thermal damage can affect fatigue life. Other researchers have found similar trends.

The NTSB said the failed landing gear on the Alaska Air Boeing 737 had overtempering (which reveals itself as a darker layer). They did not say it had rehardening (which occurs at an even higher temperature, reveals itself as a white layer, and is usually accompanied by an overtempered dark layer beneath the rehardened white layer — as shown in Figure 2). For the example in Figure 1, tempering-without-rehardening is about Level 2 — worse than Level 0 but not as bad as Level 3. This can certainly reduce fatigue life, but probably not catastrophically. However, NTSB said that overtempering (without rehardening) was the probable cause of the failure.

The NTSB said the landing gear had experienced 11,116 landing cycles when it was sent for overhaul, which included grinding. After overhaul, it suffered fatigue failure after 4,710 landing cycles. Considering that Level 0 to Level 2 might put us in the ballpark of a 50% reduction in fatigue life (or maybe 25%, or maybe 75%), and assuming the designers put in a safety factor, it seems that putting all of the blame on overtempering is a tad extreme.

Therefore, as of now, I’m not convinced.

I’ve been in grinding shops that were regrinding landing gear. If Level 2 grinding damage (overtempering, but not rehardening) is enough to cause this type of failure, I would expect to see more failures.

I’ll stop here — because I’m starting to venture too far into speculating without all the information. Also, this is complicated stuff. One must proceed with caution, even when one has all the information. But as of right now, with the information I have, I have my doubts that overtempering from grinding is the primary culprit in causing the landing gear to fail.

Related Glossary Terms

- endurance limit

endurance limit

Limit below which a material will not fail.

- fatigue

fatigue

Phenomenon leading to fracture under repeated or fluctuating stresses having a maximum value less than the tensile strength of the material. Fatigue fractures are progressive, beginning as minute cracks that grow under the action of the fluctuating stress.

- fatigue life

fatigue life

Number of cycles of stress that can be sustained prior to failure under a stated test condition.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.