Contact Details

Manufacturers, especially job shops, know better than most the pressures of ever-increasing customer demands and the equally demanding requirements to control costs. Multi-purpose tools have been one method many shops use to bridge the gap — excellent in certain materials and "good enough" in others to get the job done. Field tests are confirming the WIDIA VariTap delivers the best of both worlds: superior tapping performance in multiple work materials without sacrificing part quality or tool life.

"Job shops by nature require the broadest possible toolbox to deliver different jobs that come in daily," says Marcelo Campos, Manager Global Product Management for tapping at WIDIA. "VariTap draws on more than 140 years of application experience to provide today's shops the ability to address different applications and materials with one solution. As opposed to having to stock custom or specific taps for aluminums, stainless steels, cast irons, etc., the VariTap design gives them high performance without compromise."

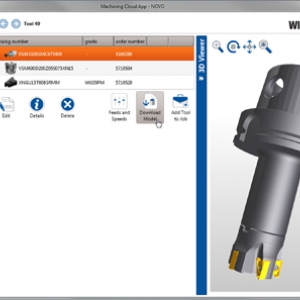

VariTap's design engineering includes a proprietary spiral point geometry that lowers tapping torque, extending tool life while efficiently driving chips forward in through holes. Optimized spiral flute geometry additionally aids chip evacuation, reducing bird-nesting in blind holes. Significant investment in WIDIA's production process includes state-of-the-art CNC tool grinders with robot loading system and advanced coating center that, combined with VariTap's high vanadium HSS-E blanks, greatly improves wear resistance. VariTap also can be used with all styles of tap holders including:tension/compression holders, rigid holders, and synchronous tap holders.

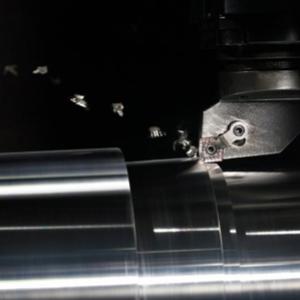

Founded in 1966 in Avon, Ind., Mears Machine Corp. supplies machined components and complex fabrications to a range of industries. Achieving a fast, competitive solution for each customer is the goal. Each job is unique, according to the company. Having the best and most advanced equipment is only part of the quality equation because experience is critical. Mears begins the quality equation with trained machinists that have extensive experience with a wide variety of materials: nickel, cobalt, iron, aluminum, and titanium-based alloys. Having the right tools is critical, as well, which is why the company was eager to test the VariTap for itself. "We love them," explains Steve Earnest, former plant manager and 20-year veteran at Mears Machine. "We had been using regular HSS taps mainly in 347 stainless. They were good quality taps, we just felt we weren't getting as much performance as we should. When we agreed to field-test the VariTaps, they lasted at least five times as long as the taps we were using, in a few cases, six."

WIDIA is not bringing just selected VariTap options to the market, but a broad array of VariTap choices, more than 1600 SKUs. "There's a VariTap for all tapping conditions," says Campos. "There are DIN dimensions for Europe, ANSI for North America, (including DIN lengths on ANSI shanks), and JIS for Asia.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- cast irons

cast irons

Cast ferrous alloys containing carbon in excess of solubility in austenite that exists in the alloy at the eutectic temperature. Cast irons include gray cast iron, white cast iron, malleable cast iron and ductile, or nodular, cast iron. The word “cast” is often left out.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.