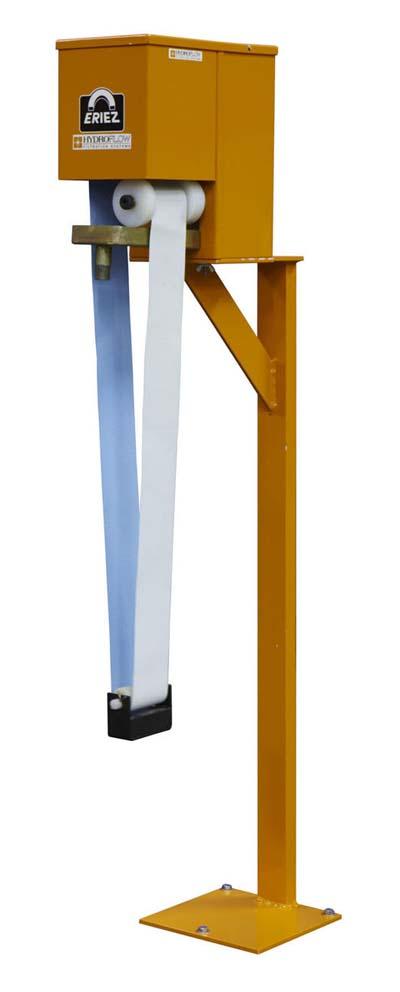

Surface Oil Belt Skimmers from Eriez Hydroflow feature a new oleophilic (oil-attracting) belt to strip separated oil from both sides of the belt. Using this method, there is no contact with a stationary scraper. This results in a great combination of excellent performance and long belt life.

Reducing tramp oil is a high priority for all metalworking shops. Excess tramp oil leads to smoke, mist and bacterial infestation of the metalworking fluids, which adversely affects surface finish and reduces tool and dimensional tolerance control. Installing the Eriez Surface Oil Belt Skimmer extends the life of coolants and cleaners, improves machining and preserves valuable tools.

This low-maintenance oil skimmer is designed for fast, easy belt changing and can be equipped with a timer so the unit runs only when the machine is idle and the tramp oils have risen to the surface. The lower hang roller will not fall off in the machine sump, even in turbulent sump conditions.

Eriez Surface Oil Belt Skimmers come with a heavy-duty, impedance-protected, fan-cooled drive motor with a hardened shaft and needle bearings, and accessible oil collecting tray with a convenient drain connector. They feature heavy-duty steel construction with industrial-grade enamel paint.

Eriez also offers a standard Surface Tramp Oil Belt Skimmer. These units have a similar "oil-attracting" belt, but use a more compact scraper blade to strip the separated oil from the belt.

Contact Details

Related Glossary Terms

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- tramp oil

tramp oil

Oil that is present in a metalworking fluid mix that is not from the product concentrate. The usual sources are machine tool lubrication system leaks.