Safe-Lock System

Safe-Lock System

Toolmaker Kennametal Inc. focuses on supplying its customers with productivity of the highest level, even when faced with challenging conditions.

Toolmaker Kennametal Inc. focuses on supplying its customers with productivity of the highest level, even when faced with challenging conditions. This includes among others HPC (High Performance Cutting), in which the capability of the machine tool is exploited to its very limits.

Oliver Sax, Manager, Global Solid End Milling Products Portfolio at Kennametal, explains: "Many segments are being subjected to fierce competitive pressure. They are looking for manufacturing solutions that give them the highest possible metal removal rates. HPC is becoming more and more popular, in particular where the proportion of metal removal is high, as it is in the aerospace industry for example. This has become increasingly evident in the last few years, ever since high performance cutting tools that facilitate this type of machining have been on the market. These can withstand the high torques, feeds and forces that occur during machining without breaking. The danger of the milling cutters being pulled out of the tool holder at these extreme forces has, however, significantly increased. This is at least true for tool holders that offer precision clamping with good concentricity such as shrink-fit, hydraulic expansion or power chucks, for example. These work with frictional locking, but their clamping force is often not sufficient for HPC. It is estimated that about 70 percent of all users are currently forced to use standard Weldon holders for heavy roughing operations due to security concerns, because the clamping screw of these holders creates a positive locking. This means that any desired torques can be transferred, but combined with the known disadvantages of poor cutting tool run-out, weak clamping due to the shank needing a little space in the chuck and shorter tool life of the expensive HPC cutting tools." Keith Wiggins, Leader Global Tooling Systems Product Management at Kennametal, has been investigating a fail-safe/high-accuracy tool holding system to complement their already high performance portfolio for a long time now and is well aware of the problems with aggressive heavy chip removal involves: "For years now we have been investigating a holding solution that has best possible accuracy with a fail-safe security clamping system that would gain the full potential from our cutting edge performance. With the Safe-Lock from Haimer we now have a high precision guaranteed non-slip holding solution to complement our toolholder offering."

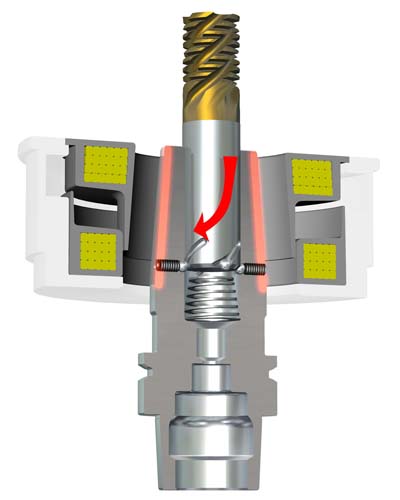

That is why Kennametal decided to sign a license agreement for the patented Safe-Lock system. This licence allows Kennametal to insert the corresponding device in the shanks of its cutting tools. In addition, the agreement enables the global cutting tool company to take the Safe-Lock shrink-fit holders into its portfolio and offering its products and services as a single-source supplier. The Safe-Lock is a pull-out protection for round shanked cutting tools of all types. The principle is simple and effective: helical grooves are ground into the shank of the tool. These together with the respective pin drivers in the chuck prevent the tool from spinning or even being pulled out of the holder altogether under extreme machining conditions, a malfunction that can be very expensive where such costly tools and workpiece materials are concerned.

The trick here: The helical path of the Safe-Lock grooves means that the length of the tools can also be adjusted. In other words the tools can be reground and pre-set as usual. The Safe-Lock allows you to use the benefits of the latest tool holder systems, such as shrink-fit technology, because it can be used without hesitation for both high-speed as well as heavy chip removal. The clamping process is simple. The chuck is heated as usual and the tool inserted with a slightly twisting movement. The locking elements of the Safe-Lock find their own way into the grooves when the tool is turned. A spring can be used to aid in the play-free positioning of the tool. The holder cools down after a few seconds creating the press fit and positive locking. Concentric accuracy of 3µm(0.00012") is achieved during shrinking, a value that is 10-times better than any standard clamping in Weldon chucks. The stable and accurate tool clamping achieved in this way allows users to machine even greater cutting depths with higher feed rates. The tangible benefits at the end of the day: time saving, enhanced productivity, lower scrap rates and less vibration.

The principle of the Safe-Lock system is not restricted solely to shrink fit chucks. It can be integrated just as easily in a collet chuck or a hydraulic expansion chuck. The Safe-Lock system has already achieved great success with high-performance tools for the HSC machining of aluminium (spiral cutters) and the heavy machining of titanium (roughing cutters). Leading companies in the aerospace industry have increased their removal rates by over 30 percent thus achieving a significant increase in productivity and machine capacity without the need for any new investments. One user in titanium processing was able to increase the tool life of his cutting tools threefold for roughing and sevenfold for finishing. But it is not only large companies that benefit from the Safe-Lock system. A medium-sized supplier of the automotive segment reports that his tools now run so smoothly that their tool life has doubled. This proves that the Safe-Lock system is well suited for all users who wish to increase productivity while at the same time achieve absolute process reliability and security for their heavy metal removal operations.

As the inventor of the Safe-Lock system, Haimer makes clear demands on any potential licensees. Suitable partners are innovative cutting tool makers who dare to take up the challenge of machining new materials and high-performance machining. "We are very happy and proud to have found a major global partner for the Safe-Lock system in Kennametal, one of the world's leading cutting tool suppliers. The flair for innovation at Kennametal for the benefit of its customers matches our own philosophy exactly," explains Andreas Haimer, Member of the Executive Board at Haimer.

Mr. Sax Manager, Global Solid End Milling Products Portfolio at Kennametal is also looking forward to the cooperation: "The progress made in the field of materials and geometries must go hand in hand with progress in both the tools used and tool clamping. The high quality of our tools combined with the innovative Safe-Lock technology from Haimer will bring the users a great step forward."