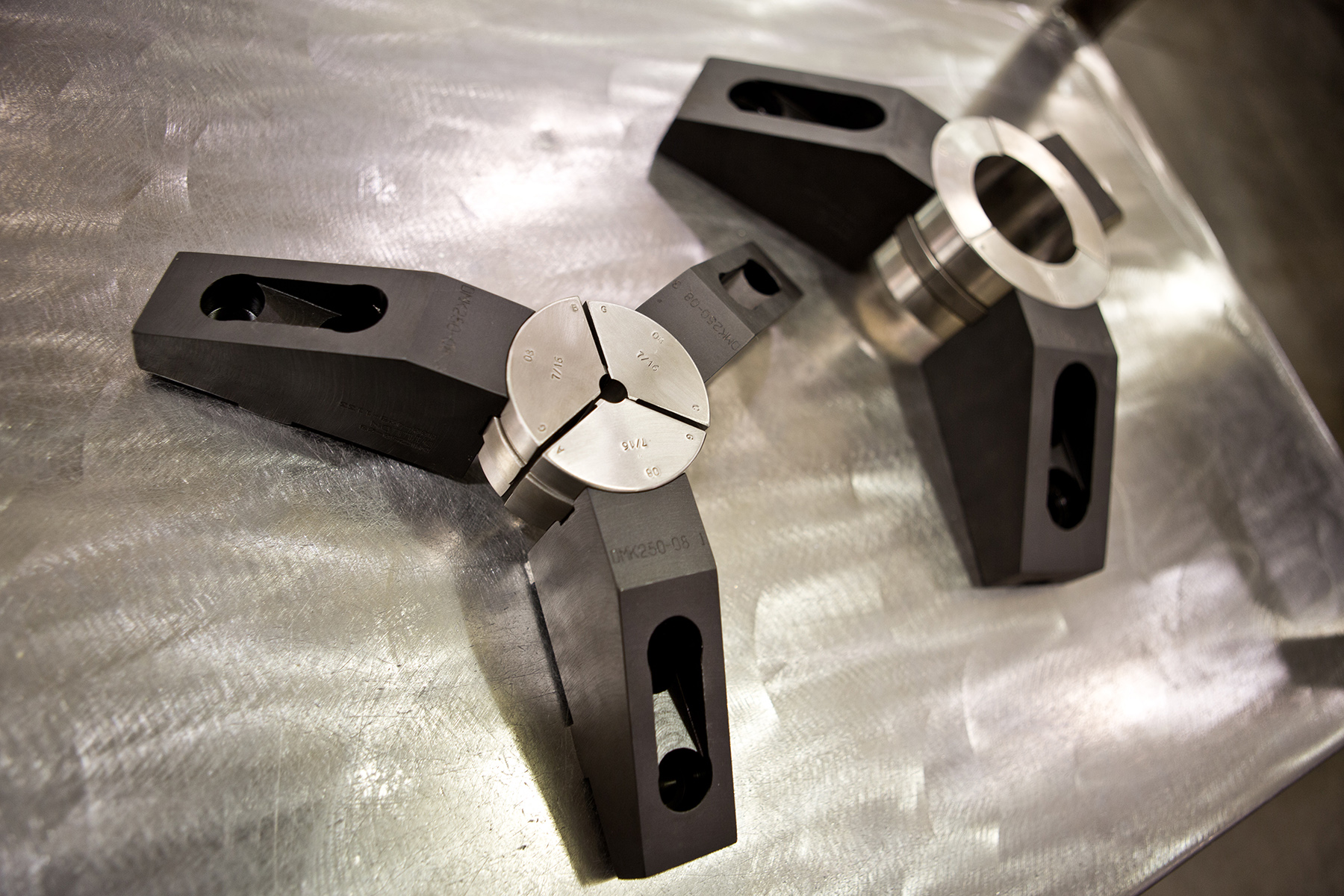

Collet Pad Jaws and Collets

Collet Pad Jaws and Collets

Collet pad top jaw systems from Dillon Manufacturing allow more varied geometries to be securely gripped, while also allowing more aggressive machining which shortens cycle times. With systems that can convert through-hole chucks to hold small bar and tube stock, and full contact of gripping surfaces to provide a more stable grip and allows heavier cuts, these Dillon products allow shops of all sizes to expand their capabilities.

Collet pad top jaw systems from Dillon Manufacturing allow more varied geometries to be securely gripped, while also allowing more aggressive machining which shortens cycle times. With systems that can convert through-hole chucks to hold small bar and tube stock, and full contact of gripping surfaces to provide a more stable grip and allows heavier cuts, these Dillon products allow shops of all sizes to expand their capabilities.

Collet pads can be changed quickly, thus maximizing production time. Jaws can be adapted to many styles of chucks, making them ideal for special-purpose machining. Dillon collet pads and jaws are suitable for precision boring, high-speed machining, tapping, drilling and finishing. They are especially suited for small-diameter machining of stems, spools, crimp assemblies, manifolds for high pressure air systems, medical parts, miscellaneous fittings, mechanical and transmission components and specialty valves.

Metal-to-metal fits ensure accuracy; round, hex and square collet pad shapes with both smooth and serrated gripping surfaces available. The line includes collet pad top jaws and W&S solid emergency collet pads, as well as S-type, Gisholt, Jones & Lamson and Martin collet pad types.

Changing over to collet pad jaws is easily accomplished in just minutes with simply a jaw change, which is much faster and easier than changeover of entire chucks. The use of collet pad jaws allows users to maximize their chuck capabilities and more fully amortize their chuck investment by performing both chuck and collet pad projects.