In the past, acquiring live tooling after a major machine purchase has usually required a substantial additional investment, one that was often out of reach for companies that already stretched the budget to acquire the best possible machine tool. In today's competitive marketplace (especially in the midst of a still sluggish economy) this additional investment can be far worse than uncomfortable: in fact it causes many companies to make decisions to procure tooling far less than complimentary to their new machine investment. That's why, for leaders focused on conserving costs and improving productivity, WTO's innovative new system can be a game-changer, according to the company. QuickFlex, an innovative flexible tooling system for driven toolholders, greatly minimizes the initial out-of-pocket tooling costs. Plus, it dramatically reduces tool change time and provides greater long term flexibility.

"Providing an ER collet chuck and quick change system in one toolholder allows you to buy many fewer tools than you would have to otherwise," says Anthony DeHart, director of sales & business development at WTO USA. "Best of all, this flexible system doesn't compromise rigidity, performance, or accuracy, which is great news for high-precision contract manufacturers."

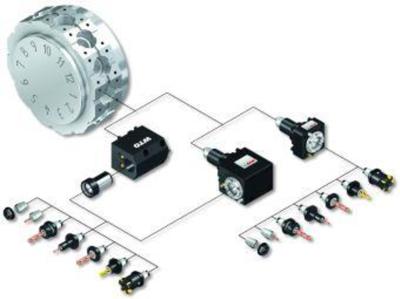

QuickFlex was officially introduced in 2012 and is now available for the North American market. It is a complete toolholder program available for the most turning centers using BMT style toolholders. Specifically, DeHart says, the QuickFlex base unit allows customers to clamp tools directly into the ER collet of the tool holder, no additional adaptor is necessary. If customers acquire additional types of tooling in the future, they can be easily be accommodated by using the QuickFlex adaptors, which are mounted directly into the base unit.

"The base unit comes in a straight (radial) or right angle (axial) configuration, which, combined with the wide range of adaptors available, covers virtually any machining process requirement, all in a single system," DeHart explains. "This approach enables the company to incrementally invest in a full range of options with minimal initial capital requirements. It also accommodates the multiple setups and frequent changeovers that are required for the short manufacturing runs in today's production environment."

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.