Large-Diameter Chucks

Large-Diameter Chucks

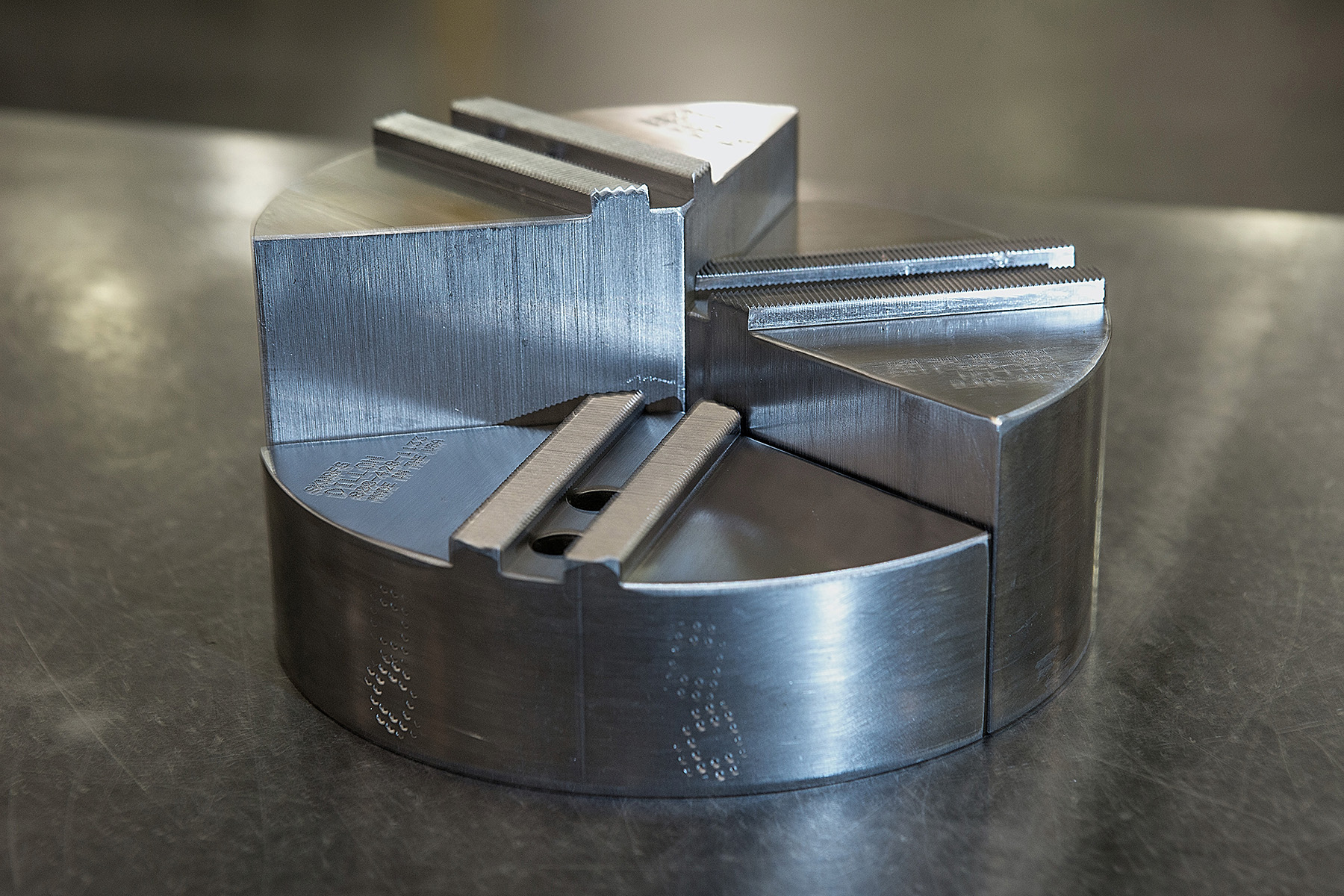

Dillon Manufacturing specializes in premium chuck jaw products for large-diameter (15-60 inch) chucks. Matching specialized workholding to the large diameter chuck allows faster, easier and more profitable setups. Available in standard configurations to fit virtually any chuck manufacturer, many sizes of hard or soft top jaws, or full grip (pie) jaws are available from stock or with industry-leading lead times.

Dillon Manufacturing specializes in premium chuck jaw products for large-diameter (15-60 inch) chucks. Matching specialized workholding to the large diameter chuck allows faster, easier and more profitable setups. Available in standard configurations to fit virtually any chuck manufacturer, many sizes of hard or soft top jaws, or full grip (pie) jaws are available from stock or with industry-leading lead times.

Available in 1018, 1045, 4140, 8620, A-2, 6061 aluminum, and stainless steel. In addition to standard designs, custom jaws with extra height or added width can be manufactured to customer specification using an "easy quote" format with "fill-in-the-blanks" convenience. Dillon standard and custom chuck jaws and collet pads and jaws aresuitable for high-speed machining, as well as precision boring, tapping, drilling and finishing across virtually all industrial markets.