Contact Details

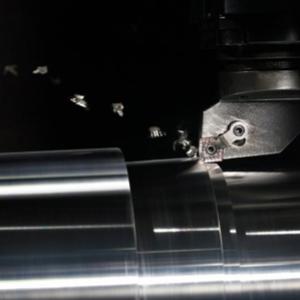

Where applications demand precise thread quality and improved threadmaking productivity, Widia offers its new high-performance WIDIA-GTD HSS-E taps. These new taps represent an effective combination of grade, geometries and coatings for accomplishing precision tapping applications in steel and stainless steel materials. The proprietary powder-metal substrate contains higher than standard levels of cobalt content for a combination of heat resistance and improved tool life. Choices include 15-degree left-hand helix for pushing chips ahead in tapping through holes or 45-degree right-hand helix for retracting chips from blind-holes. Manufactured to both ANSI and DIN standards, the precision h6 shanks allow these new taps to excel in conventional tap holders with square drive or precision round tool holders. Grades are available for general engineering and vehicle manufacturing applications, such as crank and cam shafts, connecting rods and wheel hubs. Choices also exist for precision aerospace applications, such as valves, fittings and fasteners in stainless steels.

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.