Drake Manufacturing Services Co. has recently shipped a GS:TE-LM 200 Steering Worm Grinder to a European automotive parts supplier.

The machine will finish grind the thread geometry on a steering worm shaft. It is equipped with Drake's Smart Spindle technology which features an acoustic emissions sensor mounted in the high-speed spindle. This sensor detects the sound of the wheel touching the part to within less than oneµm. In effect, the wheel becomes a probe for the part automatically equalizing stock on both sides of a thread groove. The result is a significant improvement in setup, quality and productivity.

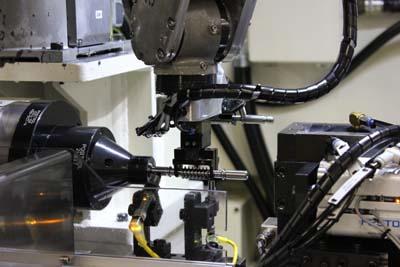

The GS:TE-LM 200 is also equipped with a Part Load Verification System. The robot picks a part off the pallet and places it in a measuring fixture in the machine. Measurement sensors detect a particular feature on the part and determine if it is correctly oriented. Once verified, the part is placed in the collet and grinding begins.

Contact Details

Related Glossary Terms

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.