Contact Details

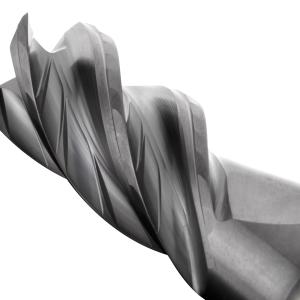

Kennametal is introducing the new BeyondTM KCPM20 grade indexable milling insert, specially engineered for high-speed dry machining in light to medium milling of steel and stainless steel parts under stable conditions. KCPM20 is being recommended as an ideal optimization grade for stainless steel machining applications where coolant is not used and excellent wear resistance is required.

Each specific Beyond grade from Kennametal is optimized with substrate characteristics and coating thickness specific to its application. The result is productivity improvement and an expanded range of application for each new product compared to the original grade.

All new Beyond inserts are CVD (chemical vapor deposition) coated, but whereas conventional CVD coatings are under tensile stress, Beyond inserts undergo a proprietary post-coat treatment on all surfaces to reduce this stress, which improves coating adhesion and reduces micro-chipping. More uniform and reliable wear of the cutting edge results in improved and more consistent tool life. Smoother surfaces also lower frictional forces, another factor that expands applications and permits higher cutting speeds.

Additionally, all Beyond inserts are top- and bottom-ground after coating for a better seating surface in the toolholder, which improves security.

New Beyond KCPM20 inserts are available in a variety of Kennametal milling cutter styles, including:

Dodeka for face milling in stable applications KSOM, where lighter cutting forces are required

Mill 1 for high-performance shoulder milling

KDM for general-purpose and die/mold machining

"While optimized for steels and stainless steels, KCPM20 also can act as a troubleshooter in cast iron applications, particularly with nodular irons in dry conditions," says Osny Fabricio, Kennametal Senior Product Manager. "Use KCPM20 when existing applications need to be optimized to gain additional tool life and productivity via higher speeds and feeds."

Related Glossary Terms

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.