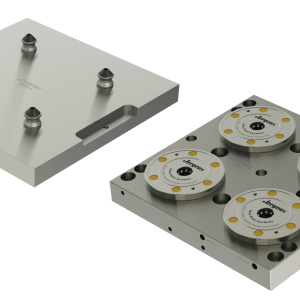

Workholding

Bluco Corp.'s precision modular fixturing

Every minute that a CNC machine sits idle while being tooled up for the next job costs money. Bluco Corp.’s modular fixturing solutions get machines back up and running in less than half the time it takes to manually set up a job. Call 800-535-0135 for more information.

Bluco Corp. | www.bluco.com