HCL Technologies (HCL), a leading global technology company, today announced a new wire EDM (Electrical Discharge Machining) module for the CAMWorks suite of CAD/CAM software. The wire EDM module includes new cutting-edge functionality that takes the design model to G-code in one click. Once the user clicks the “Solid to G-code” button, the system automatically searches the part for machine-able features, identifies them, generates all the operations with the users’ preferences and settings (including tool offsets, cutting conditions and start holes), creates the toolpaths, and posts the G-code. Using the new wire EDM module, even complex 2-axis parts, 2-axis parts with tapers, and full 4-axis wire EDM parts can now be programmed in a single click.

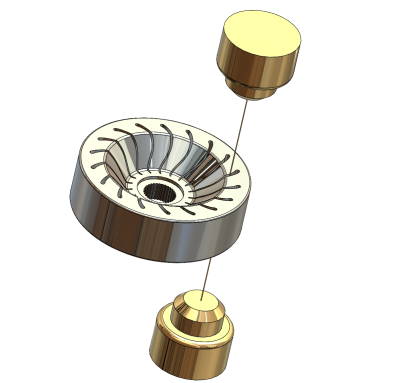

The new CAMWorks wire EDM module also includes enhanced feature recognition for non-planar geometry. Instead of the user needing to project the geometry for the top and bottom of the part and create 2D sketches, the new wire EDM software uses geometry directly from the solid model to construct and create the correct top and bottom profiles automatically.

Additional highlights include automatic angular wire threading, support for SOLIDWORKS patterns, and automation based on face colors. Automatic angular wire threading analyzes the part and automatically recognizes when angular threading would be required. It then creates the toolpaths necessary to allow for angular threading of the wire and to machine the part. Support for SOLIDWORKS patterns simplifies the NC code and streamlines the programming process by automatically identifying the patterns and utilizing them to simplify the CNC program. The technology based on face colors allows the user to easily identify and manage features that are to be programmed, as well as how they need to be machined. By assigning a color to the face of a part or to the entire part, user-defined machining strategies are assigned automatically to streamline the programming process.

The technology included in the new module has been field tested on the most advanced EDM machines and is expected to position CAMWorks wire EDM module as the easiest-to-use, most advanced wire EDM programming package available.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- solid model

solid model

3-D model created using “building blocks.” This is the most accurate way of representing real-world objects in CAD.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- wire EDM

wire EDM

Process similar to ram electrical-discharge machining except a small-diameter copper or brass wire is used as a traveling electrode. Usually used in conjunction with a CNC and only works when a part is to be cut completely through. A common analogy is wire electrical-discharge machining is like an ultraprecise, electrical, contour-sawing operation.