Contact Details

In deep-hole drilling applications up to 30XD, new solid-carbide WIDIA-Rubig deep-hole drills reportedly remove between three and four times the metal compared to gun drills, in addition to delivering excellent hole quality and cycle times.

"Three- or four-fold increases in metal removal rates mean significant improvements in a customer's bottom line, whether it be in increased throughput, additional capacity for drilling equipment, or better-utilized personnel," says Chris Merlin, senior global product manager, holemaking.

Length ratios for the new WIDIA-Rubig deep-hole drills are available in 15XD, 20XD, 25XD, and 30XD. Available diameters range from 3.0 to 13.0mm. Along with increased performance, the solid-carbide deep-hole drills increase process versatility by not requiring special drivers or guide bushings. And where gun drilling machines are dedicated to gun drilling only, WIDIA-Rubig deep-hole drills can be used in machining centers, eliminating the need for specialty capital equipment.

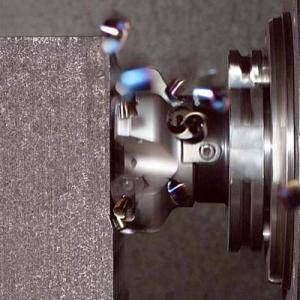

With 132-degree cone-point geometry, WIDIA-Rubig deep-hole drills have low thrust and excellent centering ability for increased hole quality. A four-margin design improves stability in the cut and an advanced PVD coating and highly polished surfaces increase wear resistance and reduce friction on margins and cutting edges.

"Higher tool life and feed rates are considerable advantages with these tools, and adding that customers will be drilling more holes per drill and getting longer life and more regrinds per drill seals the deal," Merlin adds.

Related Glossary Terms

- centering

centering

1. Process of locating the center of a workpiece to be mounted on centers. 2. Process of mounting the workpiece concentric to the machine spindle. See centers.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.