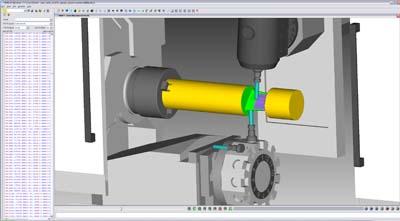

CGTech offers a new tool for communicating and collaborating with other people outside of the NC programming department. With the new VERICUT Reviewer, shop floor personnel and other production engineers can view animations of the CNC machining process.

Previously an operator would need to visit the programming office to view a program being simulated. "Since computers with graphics capabilities have become more prevalent on the shop floor, we saw an opportunity for workshop personnel to benefit from the VERICUT simulation session," said Product Marketing Manager Bill Hasenjaeger. "By creating a stand-alone VERICUT Reviewer, shop supervisors, technicians, machinists and machine operators can review a 3D machine simulation of the NC program without leaving the shop floor."

For several years VERICUT software has featured a Review Mode where the NC Programmer can play forward and backward while removing and replacing material. Error messages and NC program text is highlighted when a collision on the stock or fixture is selected. The user can optionally show cutting conditions and a tool path line display.

Now, a new Reviewer file can be saved and sent to others at any point in a VERICUT session. The VERICUT Reviewer application incorporates all the functionality of NC Review mode in a stand-alone viewer that does not require a license. The user can rotate, pan and zoom just like normal VERICUT, and the cut stock features such as material thickness, air gaps, hole diameter and pitch can be measured using the full range of X-Caliper tools.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).