CGTech offers its latest versions of VERICUT and composites programming (VCP) and simulation software. The aerospace industry continues to push for lighter, faster and more cost-effective parts. To support these goals, VCP now puts more power into user’s hands.

With more information available than ever before, part programmers can generate and export part statistics directly from VCP. The addition of the all-new summary reports allows engineers to compare different layup strategies, and feel confident the optimal design prevails.

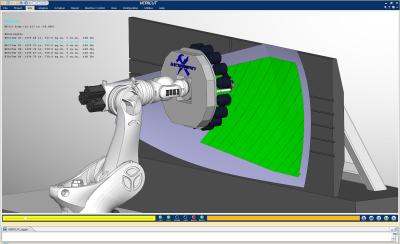

“However, one should not stop at the programming stage,” said André Colvin, CGTech’s composites product manager. “Companies now more than ever are realizing the importance of simulation and the digital twin model. With VCS users can watch their parts come to life on their machine, leaving them confident that the intended design will match what is manufactured.”

CGTech's latest version of VERICUT software, VERICUT 8.2, is an industry leading CNC machine simulation, verification and optimization software that enables users to eliminate the process of manually proving-out NC programs. VERICUT simulates all types of CNC machining, including drilling and trimming of composite parts, water jet, riveting, robotics, mill/turn and parallel kinematics. VERICUT runs standalone, but can also be integrated with leading CAM systems.

Contact Details

Related Glossary Terms

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.