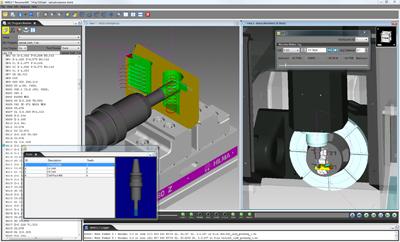

CGTech announced the next major release of its VERICUT CNC simulation software product, used world-wide to simulate of all types of CNC machines including leading brands such as Mazak, DMG MORI, Makino, Matsuura, Okuma, Haas, and Heller. In addition to new features designed to make NC programmers' jobs easier, nearly 500 customer-driven enhancements and software change requests have been completed in version 7.4. These updates utilize the latest technologies to enable faster processing speeds, longer tool life and increased part quality. Added features to the user interface simplify the most common user actions and significant developer hours have been invested to increase simulation speed by more thoroughly taking advantage of multiple processors and background processing.

"The enhancements in version 7.4 provide the speed organizations need to rapidly release new part programs to the shop floor, train new users, and continually optimize workpiece quality to ensure customer satisfaction," said CGTech Product Marketing Manager Bill Hasenjaeger. "Changes to how users interact with VERICUT further improve VERICUT's workflow and simplify day-to-day NC programming and simulation use."

Hasenjaeger continued, "We have had extensive opportunity to understand our customers' NC simulation challenges. This release increases the ability of manufacturing engineers to simulate the entire CNC machining process in order to produce better results and reduce the time spent in the programming and machining cycle. VERICUT is constantly refined to provide the flexibility and tools our customers require. We are committed to continually introducing technology to automate manual tasks and increase productivity and throughput."

In version 7.4, the first thing a user will notice is a Welcome Screen that automatically displays when first launching a VERICUT session. The Welcome Screen provides access to commonly used first actions for a VERICUT session. The VERICUT user interface continues to get more customizable. VERICUT's desktop is enhanced with a new docking method enabling VERICUT's desktop to be configured in the most efficient manner. The new docking method is very flexible and provides a high level of customization possibilities. Additionally, the Status window is completely redesigned for better viewing, customization and size. The Status window information is divided into Information Groups, each containing a specific list of information. The popular "Favorites" feature, added in version 7.3, has been enhanced to automatically read all sub-folders in a directory.

Tool Manager's desktop and user interface is redesigned to enable easier user interaction. A new Tool Bar located at the top of the Tool Manager window consists of a combination of icons and pull-down menus providing easy access to all features needed to create and maintain tool libraries, create/modify tool assemblies, import tool assemblies and create or import OptiPath records. Also, in the Tool List, tool components now have a Parent/Child hierarchy allowing for better tool assembly management and modification. All Tool Definition windows have been re-designed to make tool definition easier. VERICUT 7.4 ships with a library of common tools, making it very quick and simple to add new tools to a simulation session.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.