Contact Details

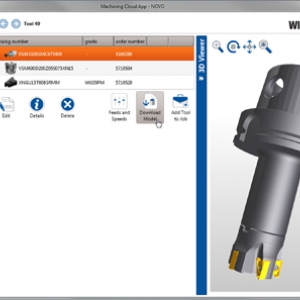

Hanita™, a WIDIA™ brand, announced the addition of metric VariMill™ Chip Splitters end mills to its high-performance tooling solutions, increasing the accessibility of efficient dynamic milling tools to customers in general engineering, automotive and aerospace industries.

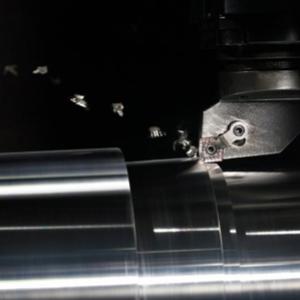

The new metric VariMill Chip Splitters feature a design that actively controls chip size resulting in easier chip evacuation in deep cavities. The end mills include five- and seven-flute configurations from 8mm-20mm metric standard diameters. The five-flute tool maximizes performance in steel materials while the seven-flute tool excels in stainless steel and high-temperature alloys.

"With the new VariMill Chip Splitters end mills we are giving customers the highest speeds and performance for side milling, shoulder milling and helical milling, and especially for dynamic milling applications,” said WIDIA and Hanita Global Portfolio Manager for Solid Carbide Milling Tamir Sherif. “We strive to offer solutions that result in increased productivity and are proud to broaden access to more efficient dynamic milling for our customers.”

The new Chip Splitters end mills are the natural evolution of the successful VariMill II and VariMill III series.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.