Contact Details

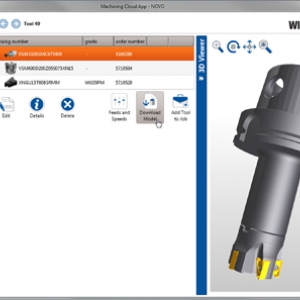

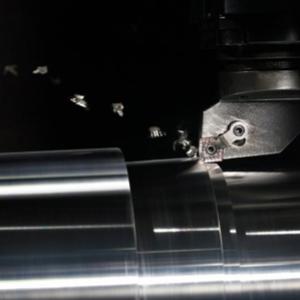

WIDIA’s Top Ream platform covers the majority of hole finishing needs, with diameters up to 42 mm (1.65 in.) and a range of edge preps and geometries available. The three keys to hole quality are diametral accuracy, form and position, and surface finish. Boring tools are the undisputed king in all of these areas, but they’re also one of the

slowest methods of hole finishing, and in most cases are limited to 10:1 depth to diameter ratios or less.

Conventional carbide-tipped reamers produce good hole quality, are substantially faster than boring and able to reach much deeper, but they also have an Achilles heel. The steel shank to which the carbide flutes are brazed has a thermal coefficient three times that of carbide, and is subject to growth during machining operations. Worse, sharpening of these tools often leads to less than desirable results. The mixture of carbide and steel wreaks havoc on grinding wheels, providing a reground edge that is rarely as good as the original tool. Also, PVD and especially CVD coating of reground tools is problematic, because the temperature inside most coating vessels reaches upwards of

530 degrees C (986 degrees F), leading to micro-movement of the brazed carbide flutes.

WIDIA Products Group has addressed these problems and more with its new Top Ream carbide reaming solution. Instead of four to eight (or more) individually brazed carbide tips, Top Ream uses a single carbide disc and brazed joint, providing a strong connection that is virtually immune to thermal effects during machining operations.

WIDIA manufacturing engineer Tom Bobos notes another important advantage of Top Ream’s all-carbide tip. “Steel-bodied reamers tend to get banged up on the ends. The center can get nicked or distorted, preventing an accurate regrind. With carbide, you always have a good center to locate on.” The result is a minimum of four “like new”

regrinds vs. an average of three questionable ones.

However, there’s more to Top Ream than its ability to hold an accurate edge. “Overall it’s just a better design,” Bobos says. “A single piece of carbide is inherently more stable and resistant to vibration. The through-hole style has an 18-degree left hand spiral that does a great job of pushing the chip forward. It’s really best in class.”

The Top Ream platform offers best in class carbide as well. WIDIA’s WU05PR advanced reaming grade was developed specifically for the demanding tool wear and surface finish requirements encountered in most hole reaming operations. For example, tests performed over a total cut distance 100 feet (30 m) in length showed an ability to consistentlymaintain surface finishes of 32 μin Ra (0.8 μm) in 4140 steel alloy and 64 μin Ra (1.6 μm) in gray cast iron, three times that of TiAlN-coated tools.

Jerry Hanna, WIDIA Director of Sales Operations, says the Top Ream covers hole diameters up to 42 mm (1.65 in.), with the TRF shank-style starting at 14 mm (0.551 in.), and the TRM modular tool from 20 mm (0.787 in.) and up. “This size range covers the lion’s share of requests from our customers,” he says. “We also offer a wide variety of custom geometries, diameters, and edge preps, all available in three weeks or less.”

If you’re worried about custom cutting tools, don’t be. “With reaming, 98 percent of the tools are custom,” Bobos points out. “We encourage our customers to try standard sizes, but they should also ask us for advice. We have the ability to optimize solutions specifically for any application—if you’re machining titanium, there are specific geometries and coatings for that. Same with 316 stainless, or Inconel. A slight tweak to the hone, or modifying the leading edge a little bit can make a huge difference in productivity and hole quality.”

One of the best features of the Top Ream is the TRM series’ mounting mechanism, which makes simultaneous contact on the cutting head’s face and taper. Twist the locking screw and the reamer head pops out, with no need for head to body orientation. This provides a strong, vibration-free, and—most importantly—extremely precise reamer interface. “There’s virtually zero runout with the modular design,” Bobos says. “Once you have everything dialed in, you just put the head on and tighten it down. There’s never a need to re-indicate after a tool change.”

Hanna agrees. “The Top Ream’s unique design is geared towards anyone that needs fine hole finishes and high productivity rates, whether it’s a Tier 1 automotive company or the small job shop down the street. And as the use of additive manufacturing and other near net-shape processes continue to grow, so too will the need for accurate, cost-effective hole finishing. That makes Top Ream an ideal reaming solution for today’s manufacturers, as well as tomorrow’s. We’re very pleased with the design.”

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- modular design ( modular construction)

modular design ( modular construction)

Manufacturing of a product in subassemblies that permits fast and simple replacement of defective assemblies and tailoring of the product for different purposes. See interchangeable parts.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- reamer

reamer

Rotating cutting tool used to enlarge a drilled hole to size. Normally removes only a small amount of stock. The workpiece supports the multiple-edge cutting tool. Also for contouring an existing hole.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- through-hole

through-hole

Hole or cavity cut in a solid shape that connects with other holes or extends all the way through the workpiece.